MDF Laser Cutter: How to Laser Cut MDF?

MDF is a widely used engineered wood preferred for making furniture, home décor pieces, wall art, etc. It comes in large sheets and is cut in the desired shape, size, and design by using a power tool. A laser cutting machine can take the experience of cutting MDF boards to the next level.

In this article, we will share the suitable laser cutter for MDF and explore how to laser cut MDF with utmost perfection.

In This Article

- What Laser Cutters are Suitable for Cutting MDF?

- Best MDF Laser Cutter

- Advantages of Laser Cutting MDF

- How to Laser Cut MDF?

- How Do You Laser Cut MDF Without Burning It?

- Laser Cutting MDF FAQs

What Laser Cutters are Suitable for Cutting MDF?

CO2 Laser Cutters

CO2 laser cutters are quite powerful, and they can cut MDF, plywood, and other wood types with perfection. The wavelength of the is around 10,600nm, which can be easily absorbed by a wide range of non-metals, such as wood, acrylic, rubber, cardboard, leather, etc., making them the most preferred option for cutting MDF.

Desktop CO2 laser cutters can cut up to 15-20mm thick MDF in one pass, depending on power. It saves too much time and ensures premium cut quality.

CO2 lasers are available in a wide range of sizes. For small businesses and home use, you can go with a desktop CO2 laser cutter. It will cost you around $3,500 to $6,000. The desktop CO2 laser cutting machines generally come with some extraordinary features, such as enclosed area, built-in air assist and exhaust fan, safety features, etc., that make MDF laser cutting even more safe and hassle-free.

Diode Laser Cutters

The second option for MDF laser cutting is diode laser cutters. These are one of the cheapest laser technologies available on the market, but they also offer exceptional performance when it comes to laser engraving and cutting.

They contain diodes that produce laser beams, which have a wavelength of 450-455nm. It is the wavelength of blue color, so it is also known as Blue Laser.

With a diode laser, you cut wood, plywood, engineered wood (MDF), acrylic, rubber, leather, and various other non-metal materials. Its compatibility of engraving is also exceptional, besides the above-mentioned materials, it can engrave stone, steel, ceramics, coated glass, coated metals, etc.

For laser cutting MDF or any other compatible material, high optical power is preferred. You should go with a 20W or above desktop diode laser cutting machine to cut thick MDF in one pass.

You can get a diode laser for $700 to $2,000, depending on the power, features, and specifications. These are good for both DIYers and small businesses.

XTOOL S1

Best Diode Laser Cutter for MDF

Best enclosed diode laser. Safe for home use. Ideal choice for both DIY and Business Projects.

Learn MoreBest MDF Laser Cutter

xTool S1: The Powerful MDF Laser Cutter

xTool S1 is a 40W enclosed diode laser cutter – the world’s first enclosed diode laser to cap such huge power. Besides 40W, the machine also comes in 20W and 10W variants. The flagship variant variant is capable of slicing 18mm wood in one pass.

Besides diode laser modules, S1 also offers a 2W Infrared Laser module, which is designed specifically for plastics and metals. Collectively, the machine can work on 300+ materials including MDF. The engraving speed of 600mm/s on MDF is something you rarely see in desktop diodes.

S1 is smartly designed for larger and bigger wood crafts. Internally, the machine’s working area is 498*319 mm. But, here’s a twist: the workspace is expandable. The Autopassthrough Technology™ lets you work on MDF sheets as long as 3000mm. You can also elevate the machine through a riser base to work on materials as high as 133.5mm.

S1 being xTool’s latest venture also includes some revolutionary mapping technology. While most desktop lasers use a camera system for design positioning and mapping, xTool employs a unique Pinpoint Positioning System. With laser spot, you can mark different points on the material, and the machine automatically sketches the layout of the shape on the software.

A smart focus system is also present. It automatically sketches a 3D layout of the surface and then dynamically adjusts laser focus. This enables the machine to engrave on curved surfaces.

New to MDF crafting? No problem, operating xTool S1 is a breeze, thanks to XCS software. Just select the material and thickness, and the software automatically suggests other parameters. The software has over 400+ preset parameters that can be used for seamless laser operation.

Safety is S1’s hallmark. It is a Class 1 Laser Product with a multitude of safety features. 360-degree flame detection, an enclosed laser filtering lid, an emergency stop button, and an efficient smoke evacuation system – all make it excellent for use indoors and outdoors.

XTOOL S1

Best Diode Laser Cutter for MDF

Best enclosed diode laser. Safe for home use. Ideal choice for both DIY and Business Projects.

Learn MoreAdvantages of Laser Cutting MDF

MDF is an engineered or composite wood, which is made from wood fibers, resin, and wax. It is a byproduct of residuals of different types of wood. Therefore, just like any other wood, a laser cutter can cut MDF.

Laser cutting is an ideal option for cutting MDF. Compared to alternative power tools such as jigsaws or circular saws, laser cutting offers distinct benefits.

Clean Cuts

The laser does not make any physical contact with the MDF that may produce cracks and chipping at the edges. Instead, it uses a focused beam of light to vaporize the material along the cutting path. This results in smooth and precise cuts that do not require any further finishing or sanding.

Minimal Waste

The laser vaporizes the wood and cuts it into pieces with a very narrow kerf (the width of the cut). This means that the material utilization is high and the waste is low. And there won’t be the large amounts of fibrous dusts produced by cutting with power tools.

However, proper ventilation is necessary because the smell of laser cutting MDF is awful. Make sure you have an exhaust system and air purifier.

High Accuracy

The laser cutter is a type of CNC machines that is controlled by a computer program that can follow any design or shape you want to cut. It can offer accuracy near to a small fraction of an inch. You can cut intricate designs, patterns, or letters with optimal accuracy and precision. No matter how many pieces you cut, all will be identical and consistent.

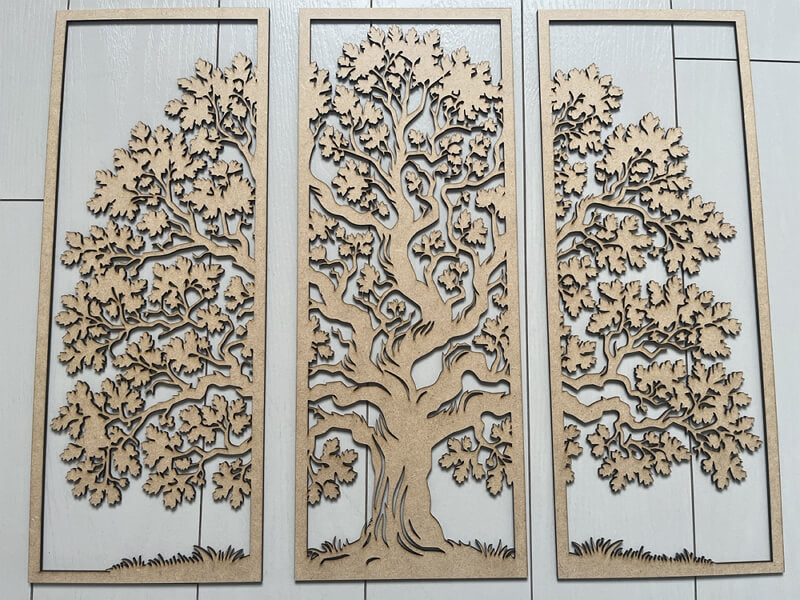

laser cut mdf wall art

Is It Safe to Laser Cut MDF?

But keep in mind that not every MDF is suitable or safe for laser cutting. Toxic fumes that can cause harm may result from the laser process. The reason is that MDF usually contains urea-formaldehyde, a synthetic resin that binds the wood fibers together. The high temperature of the laser beam vaporizes the resin, releasing toxic formaldehyde fumes.

To reduce the health risks of laser cutting MDF, you need to buy MDF that is specifically made for laser cutting and engraving, in short, laser-safe MDF. You should also laser cut MDF in a well-ventilated area with a proper extraction system to remove the fumes from the cutting area and wear protective gear such as goggles, gloves, and a respirator mask when laser cutting MDF.

How to Laser Cut MDF?

The steps to laser cut MDF vary by the laser cutter used, here are the general steps involved in the process of laser cutting MDF.

Step 1: Turn on the laser machine and connect to the computer. Open the software and turn on the exhaust system or air purifier. MDF will produce a pungent smell and harmful smoke, so it must be expelled from the working area. But if you are using an air purifier, it will remove the smell and particles from the air.

Step 2: You need a laser cut file. You can design it on your own in Adobe Illustrator, Inkscape, CorelDRAW, etc. It requires effort but ensures the uniqueness and quality of the design. You can also find free and paid files online. There are tons of websites. Get the laser-cut file and import it to the laser software.

Step 3: Clean the MDF with cloth and place it in the working area. Adjust the focus of the laser machine according to the thickness of the MDF.

Step 4: It is time to set the settings for laser cutting MDF. It is recommended to choose the speed, power, and passes wisely. Otherwise, the laser will burn the edges.

If you are cutting a 3mm MDF using a 20W diode laser cutter, you can set the power at 100 and speed at 8mm/s. Run two passes, and you will have clean-cutting results without marks even if you don’t use the air assist. If you have air assist or a more powerful laser, adjust these parameters accordingly.

It is better to have a speed and power test on a spare piece to get a complete idea of the optimal laser cutting MDF settings. Check the settings for xTool machines.

Step 5: Finally, you are ready to cut MDF. Check the framing to ensure the design is in the right place. Start the machine and wait for the process to complete.

Step 6: After cutting, take out the MDF. If the edges have too much soot, you can clean them using a piece of cloth or wipes. Then assemble the cut pieces for the finished project. You can also pain or stain the pieces before assembly.

XTOOL S1

Best Diode Laser Cutter for MDF

Best enclosed diode laser. Safe for home use. Ideal choice for both DIY and Business Projects.

Learn MoreHow Do You Laser Cut MDF Without Burning It?

Choose the Right Parameters/Settings

This is the most important step to prevent MDF from burning. You need to choose the optimal power, speed, and number of passes to get the best results. Take a spare piece of MDF to run the power speed test. It will give you the whole idea of what parameters you should select.

For MDF, it is preferred to cut it at a higher speed to prevent burning and marks. You can set two passes at a higher speed, and it will give you better results compared to slow speed, high power, and one pass. It will not burn MDF from the edges.

Use Air Assist

An air assist offers a powerful blow of air that removes the smoke from the object. It prevents burning and improves the cutting speed and capability of the laser. It is a must-have for cutting MDF or any other material.

Improve Exhaust System and Ventilation

A poor exhaust system can be a cause of burn marks. The smoke contains particles that get stuck to the mdf surface. If you don’t remove the smoke from the laser working area, it will accumulate near the object, which favors burning and leaves permanent marks.

Use Honeycomb Panel

The smoke produced while cutting wood is trapped at the bottom. It increases the temperature of the object and favors burning. It also changes the color and leaves burn marks. You should use a honeycomb panel to accelerate the exhaustion.

Stick Masking Tape

Masking tape is quite helpful. It can prevent the burning of the edges. You can apply the tap on the surface of the MDF before cutting. After the process, remove the tape. You will have clean and unburnt cuts on MDF.

Laser Cutting MDF FAQs

What Thickness of MDF Can be Laser Cut?

How thick of MDF can be cut depends on the laser type and power.

Is MDF or Plywood Better for Laser Cutting?

MDF and plywood have different pros and cons for laser cutting. MDF is cheaper, smoother, and easier to cut than plywood, but it is also softer, less durable, and more prone to warping.

Plywood is stronger, more rigid, and more resistant to moisture and heat than MDF, but it is also more expensive, harder to cut, and more likely to delaminate.

The best material for your laser cutting project depends on your budget, quality, design, and application. You should test both materials before starting your project.

Can You Paint MDF before Laser Cutting?

Yes, you can paint MDF before laser cutting, but you need to use the right type of paint and apply it evenly and thinly. Some paints may contain chemicals that can damage your laser cutter or create toxic fumes when heated by the laser beam.

Painting MDF before laser cutting can enhance the appearance of your final product, but it may also require some adjustments to your laser settings.