Acrylic Laser Engraving: All You Need to Know

Acrylic, also known as Plexiglass, stands out as a durable substitute for glass, which is notorious for its brittleness and breakage risk. It matches glass in optical clarity and is available in various hues, endearing it to artisans and crafters.

One of the most exciting aspects of working with acrylic is its compatibility with laser cutting and engraving technologies. This opens another channel of possibilities and creative opportunities. Bespoke acrylic signs, innovative LED light displays, and unique ornaments – all can be made by laser engraving acrylic.

This detailed guide explores the acrylic laser engraving process, highlighting the most appropriate type of acrylic, the best acrylic engraver, and some laser-engraved acrylic projects.

In This Article

- Types of Acrylic for Laser Engraving

- What Types of Laser Engravers Can Engrave Acrylic?

- Best Laser Engraver for Acrylic

- How to Laser Engrave Acrylic?

- Tips for Acrylic Laser Engraving

- Laser Engraving Acrylic Applications and Ideas

- FAQs On Acrylic Laser Engraving

- Conclusion

Types of Acrylic for Laser Engraving

The acrylic is chemically known as PMMA (polymethyl methacrylate). However, two different processes are used to achieve the polymerization, which results in two types of acrylics: extruded and cast acrylics.

Although both of them are made from the same base molecule (methyl methacrylate), the manufacturing process alters the physical properties of the two.

Cast Acrylic

Cast acrylic is manufactured by pouring liquid acrylic monomers into molds, where they undergo a process called polymerization (around 95%). This method results in a material that offers uniform thickness and excellent clarity.

During casting, multiple color pigments can be added. That’s why cast acrylic usually comes in multiple colors and thicknesses.

One of the hallmark features of cast acrylic is its superior response to laser engraving. When engraved, cast acrylic produces a frosty, white contrast against the clear material. It’s ideal for making awards, signage, and decorative items.

Extruded Acrylic

Extruded acrylic is made by pushing acrylic monomers through a die, creating long sheets of acrylic that are then cut to size. This process aligns the molecules in a single direction, giving a directional grain. It also affects the material's strength and how it reacts to stress.

Cast vs Extruded Acrylic: Which is the Best Acrylic for Laser Engraving?

Both acrylics look exactly the same. One can only get to know the type by looking at the manufacturer's specifications. Another hint is color. Colored acrylic is mostly cast as it is easy to add color during the casting process. However, that’s not the case always.

For laser engraving, cast acrylic is more suitable as it provides more clear results. You can achieve similar results on an extruded one. However, it takes time to adjust and optimize the laser parameters for extruded acrylics.

What Types of Laser Engravers Can Engrave Acrylic?

When it comes to desktop laser engravers, there are two choices: CO2 lasers and diode lasers.

CO2 Laser Engravers

CO2 laser engravers have 10,600 nm wavelength which is readily absorbed by acrylics. So, they can engrave and cut both clear and colored acrylics with ease.

They also come with more optical power, so cutting with CO2 lasers is also possible. CO2 laser engravers are best for small businesses venturing into acrylic crafts.

However, they are generally costlier than their diode counterparts. A desktop CO2 laser engraver is priced between $3,000 to $6,000.

Diode Laser Engravers

Diode laser engravers are generally compact and less expensive compared to diode laser engravers, making them an ideal choice for DIYers. The pricing starts at $1,000 for entry-level engravers.

However, diode lasers have a shorter wavelength, and they pass through transparent acrylics unabsorbed. They can only be engraved on colored or opaque acrylics. If you want to engrave clear acrylic with a diode laser, you need to apply a masking layer on the top.

XTOOL S1

Best Diode Laser Engraver for Acrylic

Best enclosed diode laser. Ideal choice for both DIY and Business Projects.

Learn MoreBest Laser Engraver for Acrylic

As mentioned earlier, CO2 lasers are the best for engraving any type of acrylic. xTool P2 is one of the powerful and most popular laser engravers on the market.

xTool P2: The Best CO2 Laser Engraver for Acrylic

P2 comes with a 55W laser module, which is capable of cutting 20mm acrylic in a single pass. The engraving speed of 600mm/s is also unmatched. That means, making design acrylic pieces is the task of minutes. Also, being a CO2 laser, P2 works on all types of acrylic, regardless of their color, thickness, and texture.

Internally, this CO2 laser engraver has a large bed, measuring 26 by 14 inches, which is 50% more than what competitors offer. This size is enough for most of the acrylic projects. The length further expands with an automated pass-through slot to accommodate 118 inches long materials.

To get the precise focus and internal view of the workspace, there’s a dual 16MP HD camera system inside. This system aids not only provides a real-time preview of the workspace but also aids in batch engraving i.e. engraving on multiple objects simultaneously.

Working on pre-made curved acrylic ornaments is also possible. Its Curve Ace Technology™ ensures that details on curved surfaces are as good as the flat ones. Working on cylindrical objects is also a possibility with an attachment, RA2 Pro.

Although xTool P2 supports Lightbun, the machine’s use is relatively easy with our custom software, XCS. No prior experience is required. Just place your material, connect it to the software, and drag and drop the design. P2’s measurements are quite accurate with our new DistiMaster™ Ranging System that employs LIDAR.

More power means more caution. P2 has been designed with utmost safety. It’s enclosed and features a laser-filtering lid. The machine auto locks during operation, however, there’s an emergency stop button in case of an accident. P2 comes with the world’s first fire safety set, which is fully capable of detecting, alerting, and putting off fire.

How to Laser Engrave Acrylic?

Laser engraving acrylic is a fairly easy job if you have a powerful CO2 laser engraver like xTool P2. However, acrylic can also be engraved with diode lasers but that requires a little more effort.

Here’s a detailed step-by-step on how you can engrave acrylic with any desktop laser:

Step 1: Choose Suitable Acrylic Type

Choosing the right type of acrylic is the key to getting the desired results. Cast acrylic is generally preferred for laser engraving because it produces a frosty, white contrast that is visually appealing.

Next, decide between clear or colored acrylic based on your project's requirements. Clear acrylic is great for a subtle, sophisticated look, while colored acrylic adds a vibrant touch. Ensure the acrylic is at least 1/8 inch (3mm) thick to make the designs stand out prominently.

You may check xTool’s diverse range of acrylic sheets that are specially made for laser engraving.

Step 2: Remove the Protective Layer

Acrylic sheets often come with a protective plastic layer to prevent scratches during transportation and handling. It will melt during the engraving and distort the design. So, carefully remove this layer before you start engraving.

Step 3: Apply Masking [Optional]

If you're engraving clear acrylic with a diode laser, apply a masking layer on top. You can use watercolor, tempera paint, or a dry-erase marker for masking.

If you're working with a CO2 laser or using opaque acrylic, you can usually skip this step.

Step 4: Import Your Design in Laser Engraver Software

Place the acrylic sheet inside the laser and then import a design you want to etch into laser engraver software. Simply lettering designs can be made within the software.

Step 5: Optimize Engraving Settings

Firstly, prioritize the manufacturer-recommended settings for the acrylic's thickness. However, if they aren’t available for that thickness, conduct a dry run on a test. Find the optimal setting based on the obtained results.

Step 6: Post-Engraving Cleanup

After engraving, if you apply a masking layer, your first step will be to remove this masking carefully to reveal the engraved design. Then, clean the acrylic piece to remove any residue or dust.

A soft, lint-free cloth slightly dampened with water or an acrylic cleaner can be used for this purpose. Avoid using harsh chemicals or abrasive materials that could scratch the acrylic surface.

XTOOL S1

Best Diode Laser Engraver for Acrylic

Best enclosed diode laser. Ideal choice for both DIY and Business Projects.

Learn MoreTips for Acrylic Laser Engraving

Besides the procedural steps, these few acrylic engraving tips can help you get the best results:

Find Your Perfect Settings

Before starting your project, conduct a power-speed test on your acrylic. This will give an idea of how deep the cuts get on certain power and speed. You can optimize the values for your own use case.

At the basic level, the faster the speed, the less depth you will get. The inverse is true for power, more power is more depth. This should give you an idea of what to expect to see in your test results.

Decide on the Protective Layer

Acrylic sheet usually comes with a protective covering on both sides, typically made of paper, but sometimes plastic. Some people leave it on, and pick out the remaining pieces from their project later.

Everything the laser touches should get vaporized, making this a viable option, but I've found picking afterwards to be tedious and sometimes melted bits don't want to come out of the small details. For that reason, I habitually remove the paper unless only cutting.

Adjust Air Assist Wisely

When working with wood, air assist is ideally set to a low output as a way to keep smoke and particulates from collecting on/in cone type assist nozzles, as well as from the laser's lens. Higher air volume or pressure during engraving causes a fading effect on the engraving, a less appealing result more often than not.

Acrylic reacts differently to air assist when it comes to cutting. Instead of faster/more efficient cuts, you get slower ones. This isn't all bad though. In close examination of cutting acrylic, the cuts with air assist tend to be cleaner and there is less warping or bubbling of the surrounding area.

When carving, air assist tends to result in having an extra whitish appearance. Without air assist, the color is closer to the original, but material warp/bubbling may be evident.

Leverage Acrylic for Photo Engraving

Can you engrave photos on opaque acrylic with a laser engraver? Yes, of course you can. The light touch of the laser turning the surface whitish is excellent for photos.

In some ways, opaque acrylic is easier to work with than wood, as its properties are very consistent and the surface is ultra-smooth. This eliminates a lot of the frustrations of working with organic materials.

No more, "I had it dialed in perfectly on my practice sheet but it looks like garbage on my real one!" With a bit of fiddling, one can even get a really good greyscale upper/lower boundaries for beautiful lifelike photos minus the dither processing algorithms telltales.

Explore the Potential of Mixed Media

Just because we're talking about laser engraving on acrylic, that doesn't mean that you're stuck with the natural appearance that acrylic has to offer. Quite the contrary. It's suitable for multi-layer paint works, like used with ceramic tiles and canvas. Laser foil is a particularly good pairing, the smooth surface of acrylic being ideal for adhesion.

Because acrylic can be carved out like wood and gets a tad gooey when touched by the laser beam, powder coating media works well, as does mica. For all of the combinations mentioned above, the same techniques used for wood apply to acrylic, only the power and speed changing.

Laser Engraving Acrylic Applications and Ideas

There has been a lot of discussion on the technicalities of the crafting process. Now, let’s move on to the real applications.

Here’s a list of projects and ideas that showcase the potential of laser-engraved acrylic:

Engraved Acrylic Awards

Awards are a popular way to recognize one’s achievements. Acrylic is now a common choice for making awards these awards. With a laser machine, you can etch text, logos, and intricate designs directly onto the surface of acrylic blocks or plaques.

The laser precisely cuts into the acrylic, leaving behind a frosted appearance that contrasts beautifully against the clear material. With this method, you can achieve high levels of detail and even engrave images on awards.

Engraved Acrylic Signs

Acrylic signs are versatile and can be laser engraved to fit any theme or branding – be it office directories, door signs, or decorative pieces for weddings and parties. You can carve out letters, numbers, or any design onto an acrylic sheet to make a signboard that board stands out.

Additionally, these signs can be further personalized with the addition of color or by using different types of acrylic, such as frosted or colored sheets, to match the desired look and feel.

Engraved Acrylic LED Light

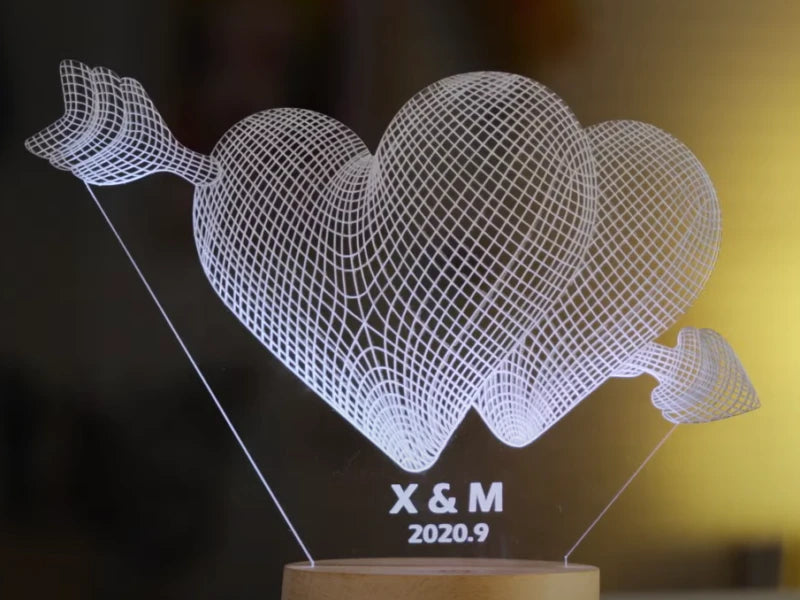

An engraved acrylic LED light is a creative and eye-catching application of laser engraving technology. You can add a design (a beautiful landscape or portrait image) onto a piece of acrylic and then add LED lights to that piece. When the LED lights shine through the acrylic, the engraved areas catch the light creating a luminous display that highlights the intricate details. This technique is perfect for creating personalized night lights, and decorative lamps.

Engraved Acrylic Ornament

Acrylic ornaments can also be made via laser engraving. You can laser cut acrylic sheets into different ornament pieces and etch them with names, dates, or artwork. The durability of acrylic coupled with the precision of laser engraving ensures that these ornaments can be cherished keepsakes for years to come. Their lightweight nature makes them perfect for hanging on Christmas trees, car mirrors, or as window décor.

Acrylic Laser Engraved Wedding Invitations

Acrylic laser-engraved wedding invitations offer a unique and sophisticated twist to traditional paper invites. By engraving the wedding details directly onto acrylic sheets, couples can give their guests a glimpse into the elegance and theme of their upcoming nuptials. This modern take on wedding invitations sets the tone for an unforgettable event and leaves a lasting impression on all who receive them.

Engraved Acrylic Keychains

Engraved acrylic keychains are a popular and practical application of laser engraving. They are lightweight, sturdy and durable. You can make them for personal use, as a gift, or for business branding.

With laser engraving, these keychains can be tailored to feature logos, names, contact information, or any motivational quote for the recipient. Furthermore, they can be customized and used as promotional items to market your brand.

XTOOL S1

Best Diode Laser Engraver for Acrylic

Best enclosed diode laser. Ideal choice for both DIY and Business Projects.

Learn MoreFAQs On Acrylic Laser Engraving

Is Cast or Extruded Acrylic Better for Laser Engraving?

Both cast and extruded acrylic are chemically the same. However, the manufacturing processes, casting, and extrusion respectively, alter the physical properties of the two. When laser engraved on similar power, the results are vivid and better on cast acrylic. That’s why, it’s recommended for laser engraving.

How to Engrave Clear Acrylic with a Diode Laser?

Diode lasers pass straight through clear acrylic. So, you need to add a masking layer on the top that absorbs the laser. Use water-washable masking like tempera paint, watercolor paint, chalk paint, and dry-erase marker when working on transparent acrylics.

What Wattage Laser to Engrave Acrylic?

Every machine comes with a wattage label, which mentions the optical power of the laser i.e. how much intense it is. For engraving acrylic, a wattage of 10 to 15W is fine. Laser cutting acrylic requires slightly more power, at least 20W.

Wrapup

Clearly, there is a lot you can do with acrylic beyond just cutting out shapes for earrings. The key to success with acrylic laser engraving is right up there at the top, in the tips section.

One little test will provide you with a wealth of information which you can then leverage for any number of laser engraving projects. Straight acrylic, acrylic plus one or more other media, surface colors, depths, you name it. Don't limit your creativity or your product lines. Explore, experiment, and develop both yourself and your business.