Key Features

Validated by the Pioneers of Digital Fabrication

Why Choose xTool MetalFab for Education?

Grant Opportunities for xTool MetalFab

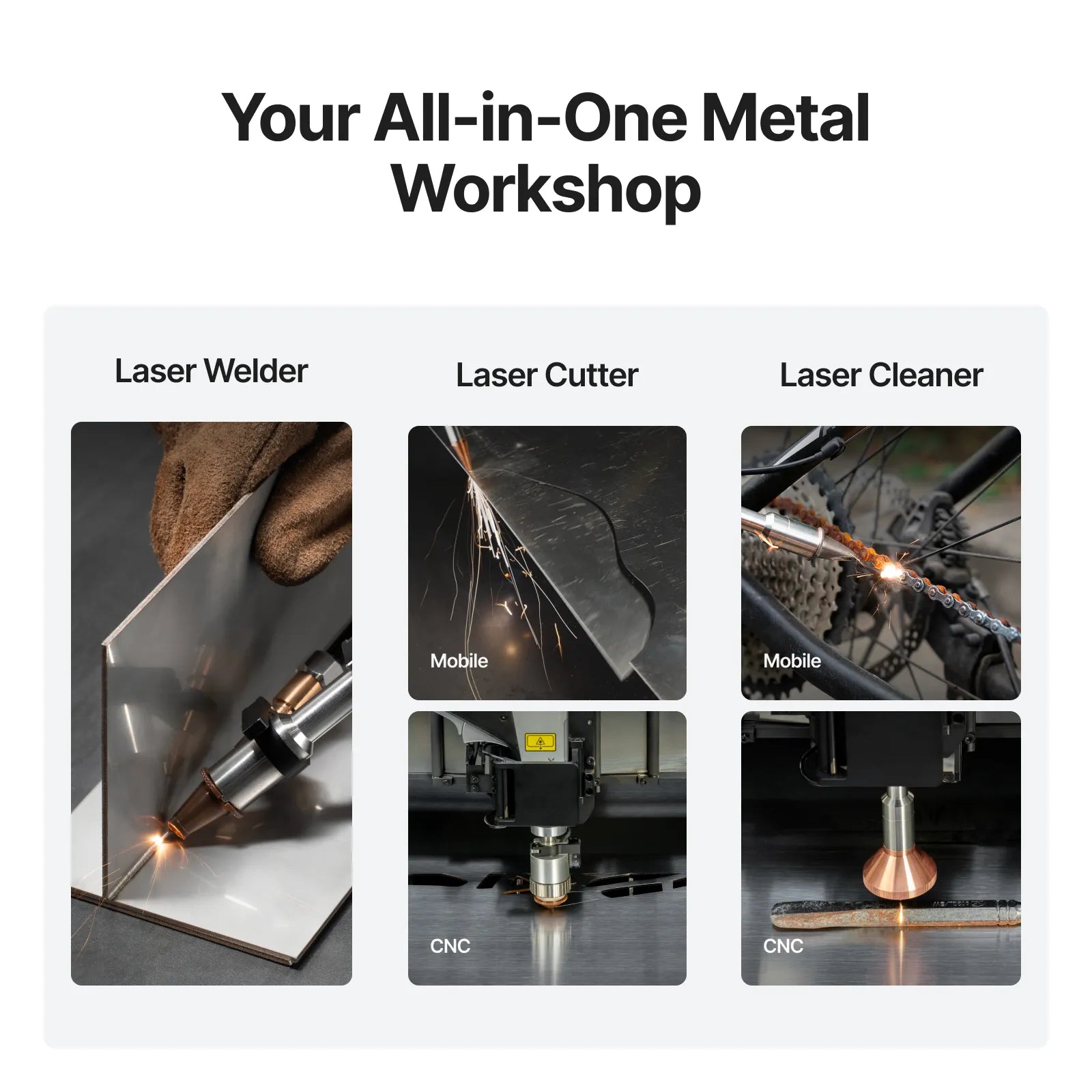

Your All-in-One Metal

Workshop.

Weld, Cut, Clean, and Engrave. All with One Device.

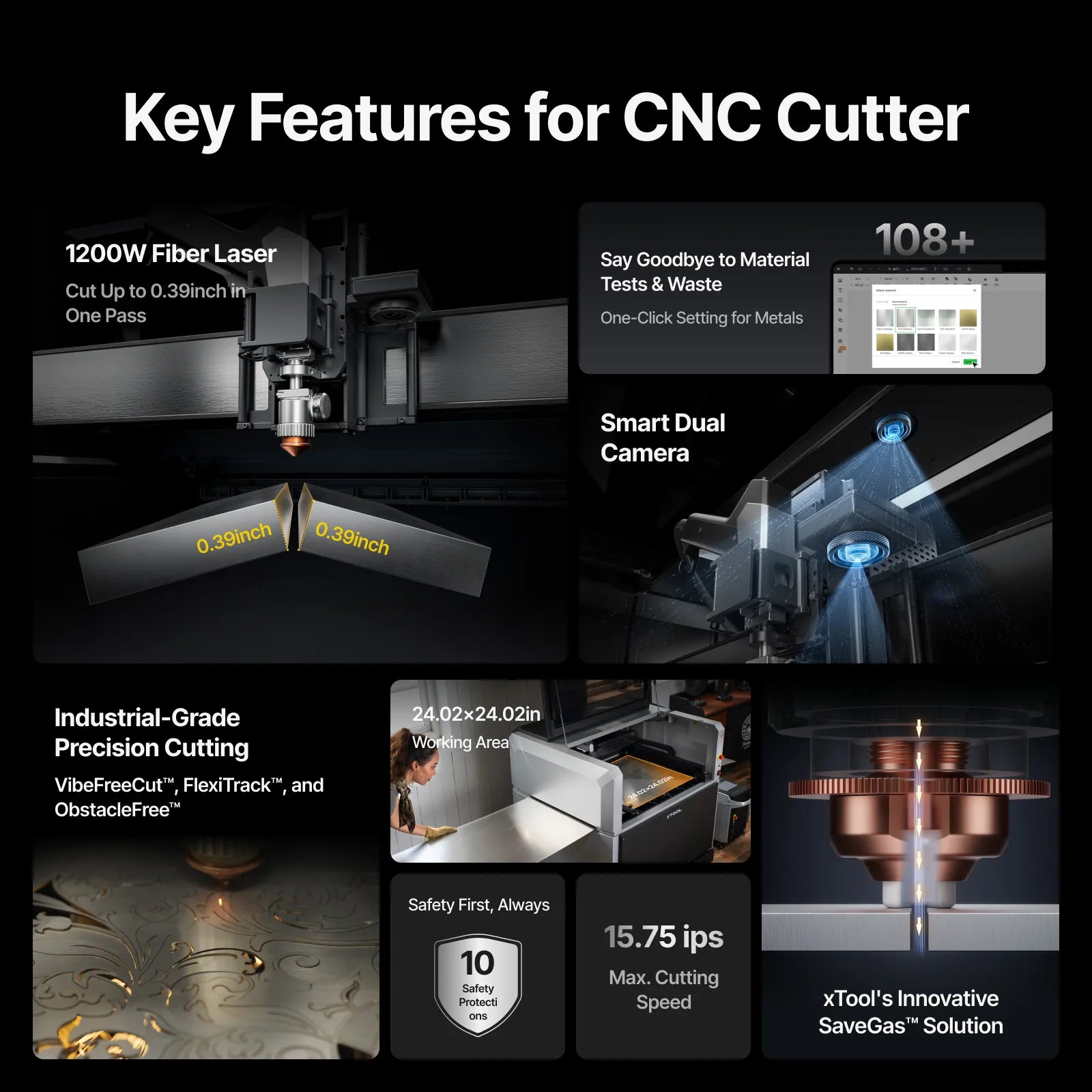

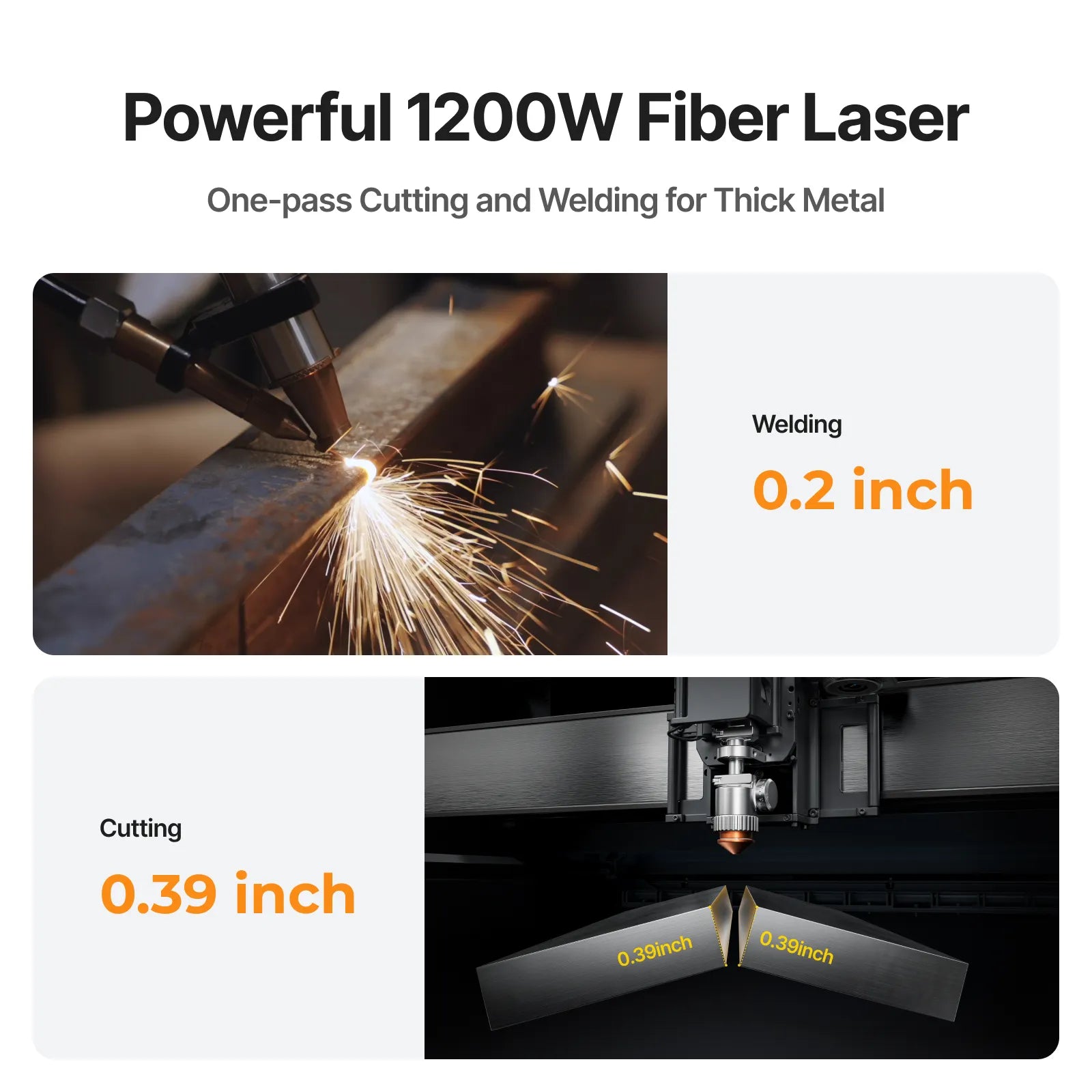

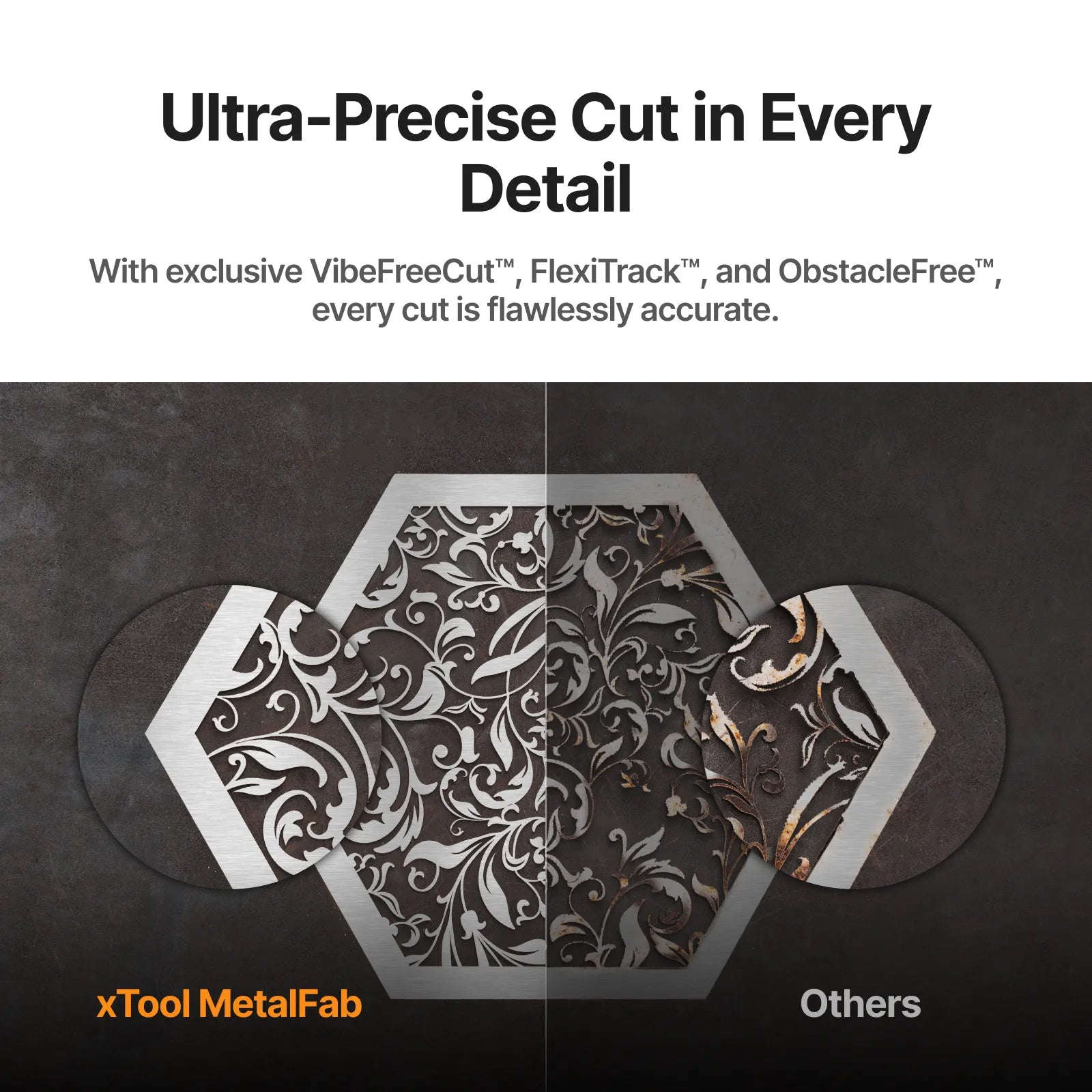

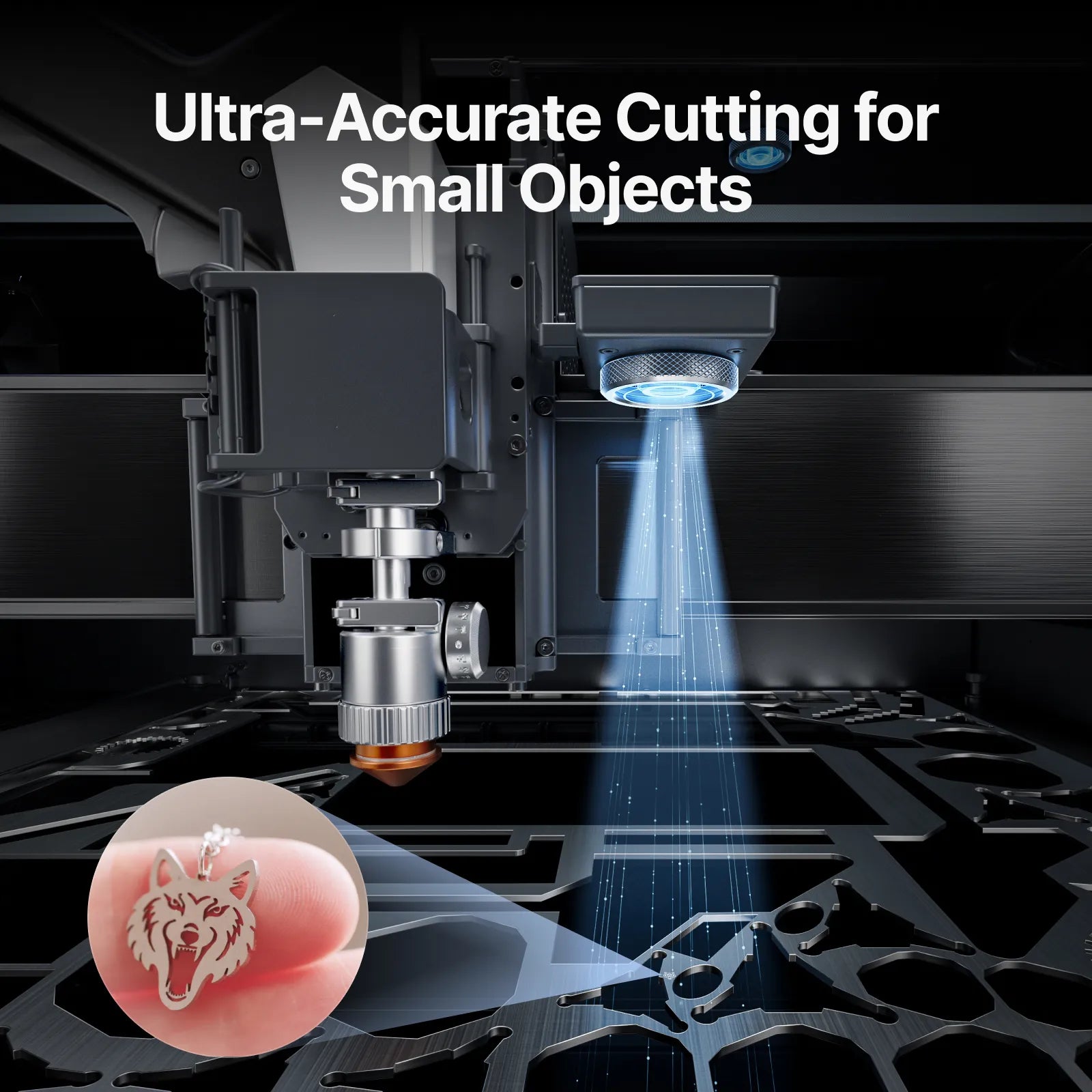

Where Power Meets Precision: The Perfect Cut, Every Time

Experience Unmatched Cutting Power and Precision with the xTool MetalFab, Delivering Flawless Results for Every Project, Every Time.

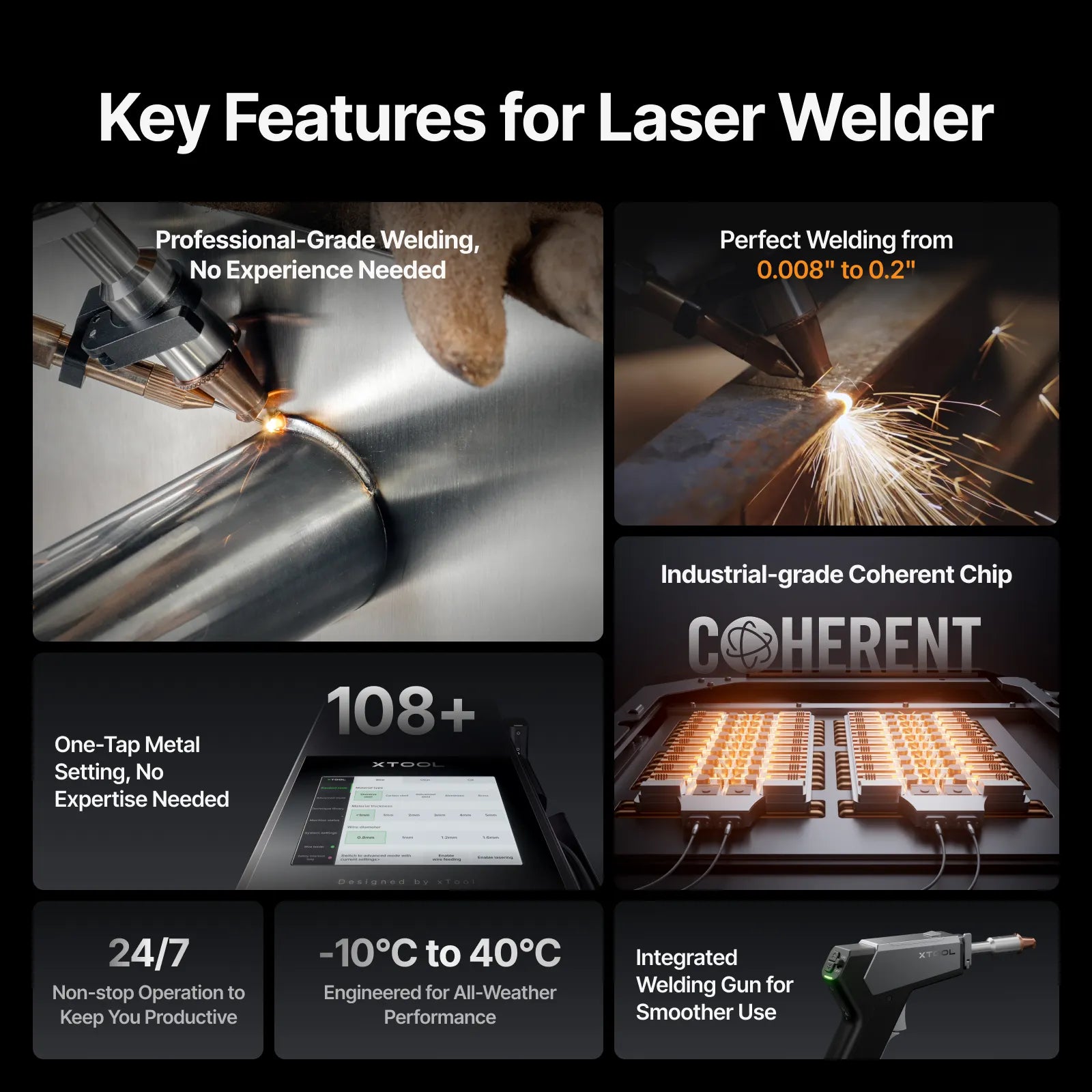

Master Every Weld, No Matter the Metal, Thickness, or Joint Type.

Fiber laser technology minimizes heat-affected zones to ≤0.002 inches (0.05mm), enabling precise welding of thin metals without distortion. Its high-energy output ensures rapid metal melting, allowing single-pass welding for materials up to 0.2 inches (5mm) thick. With this technology, deep and narrow welds are achieved with stable and consistent quality.

Powerful Software Makes Creation Effortless.

Empower Students, Not Intimidate Them

The best tools are the ones students can use confidently. The MetalFab removes technical barriers with an incredibly intuitive workflow, allowing students to focus on design and creation, not complex machine setup.

8× Faster Welding – Maximizing Efficiency Beyond TIG

Laser welding delivers ultra-high energy density, completing a 0.79-inch (20 mm)-long carbon steel weld in just 14 seconds—compared to 2 minutes with traditional TIG. That’s 8× faster, with no compromise on strength.

It’s Proven to Last 30% Longer Than Others.

Built with high-quality industrial-grade materials, a Coherent chip, advanced temperature adaptability, intelligent thermal control, and high-performance cooling, the device delivers stable performance even in extreme temperatures (-10°C to 40°C). The design minimizes overheating risks, ensuring long-term reliability and cost-efficiency during high-load and extended operations. With a lifespan exceeding 10,000 hours, it outlasts competitors by 30%.

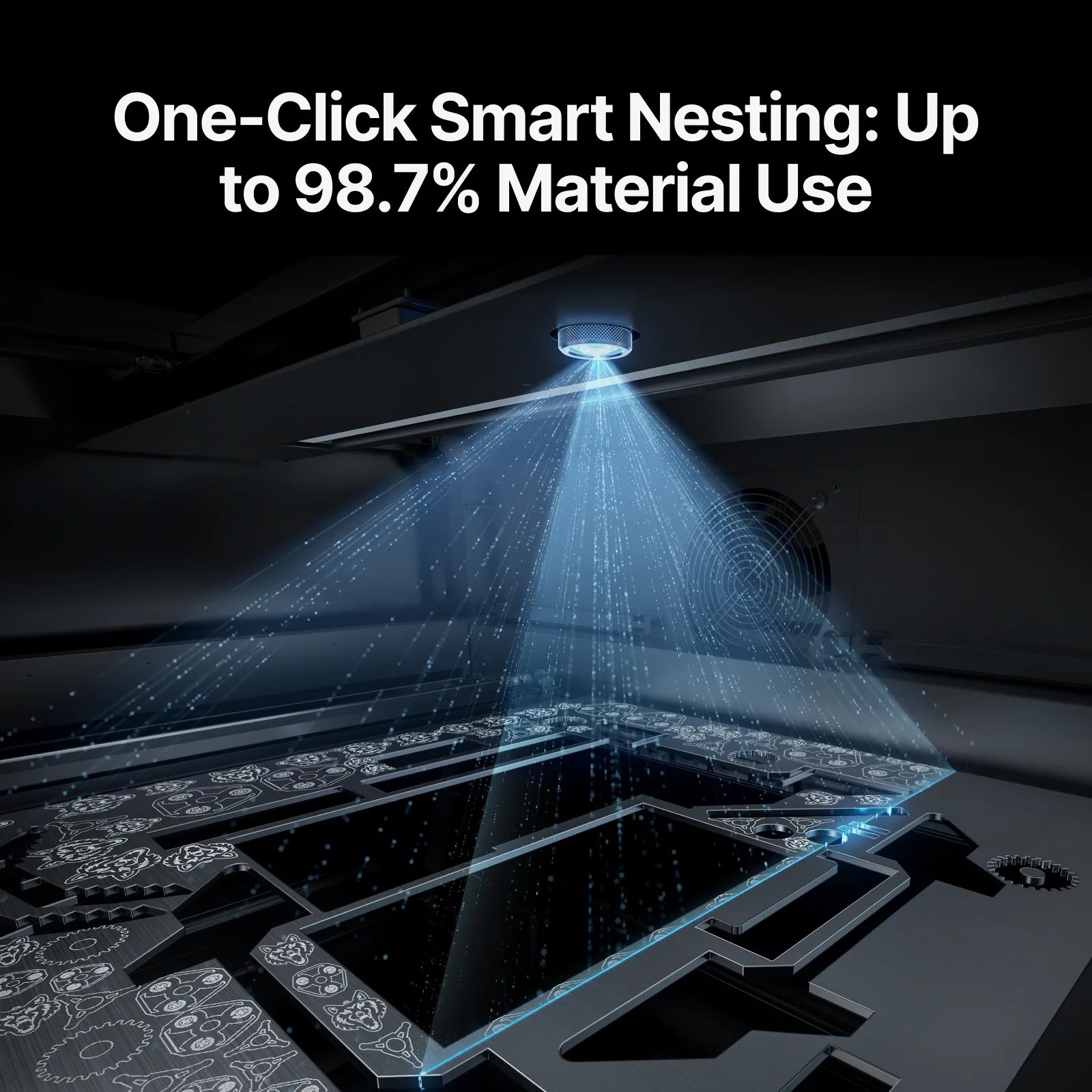

Maximize Your Budget, Minimize Your Waste

We know that every dollar and every piece of material counts in an educational setting. The MetalFab is engineered with groundbreaking technology designed to drastically lower your operational costs and make your resources go further.

Why Metal Fab Over Others?

Made with Care for Your Best Experience

Save $20,000+/Year with xTool SaveGas™ Solution

*Calculation method: 4-hour processing per day, 248-day processing per year. The cost of nitrogen gas charging is calculated at $0.30 per liter. The actual usage duration and costs vary by region.

Explore, Learn, and Connect with 2,000+ Like-Minded Insiders

Genuine Praise from Experts

What Experts Are Saying

In the Box

FAQ

The xTool Metalfab is CE, FCC, and FDA certified, meeting stringent safety and quality standards.

Due to metal fumes generated during welding and cutting, an external ventilation system (ducting outdoors) or a certified air purifier is mandatory to meet classroom air quality standards.

We have designed xTool MetalFab to ensure a smooth and simple user experience, so you don’t need to worry about lacking experience—you can get started in just five minutes!

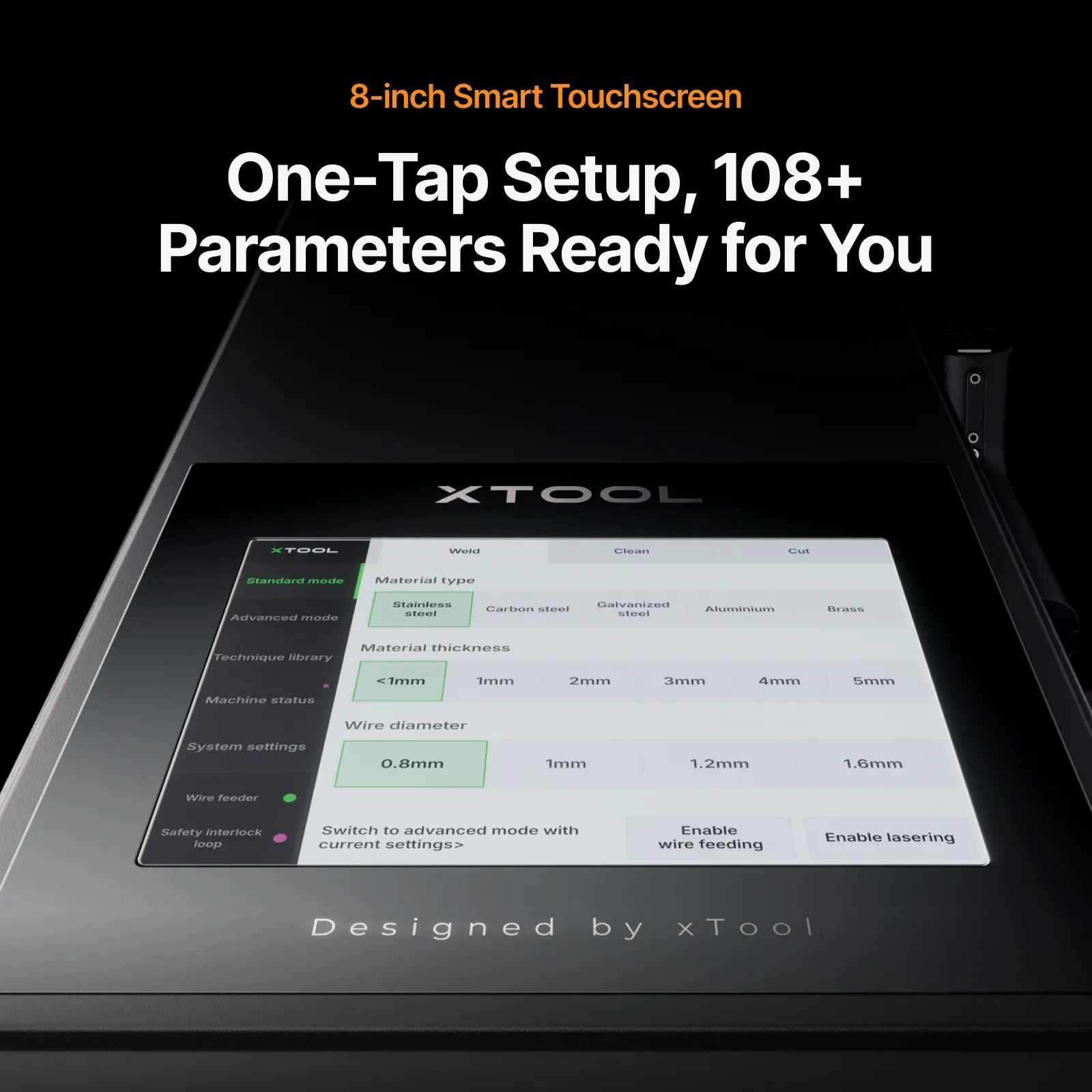

It features the 550g ultra-light integrated welding gun which enables a 5-second quick-release. The 8-Inch Smart Touchscreen has 108+ built-in parameters for one-click use.

xTool MetalFab can weld up to 5mm stainless steel or carbon steel, and we have passed SGS welding quality tests, so you can rest assured about its performance and reliability!

Comprehensive tutorials, including unboxing, operational guidance, and feature overviews, are available on our official YouTube channel.

xTool MetalFab operates on the XCS Software, designed for intuitive control and streamlined workflows:

It features the Material EasySet Library with 100+ pre-optimized parameters for 30+ materials. You only need to select the material you want to cut, and all parameters can be applied with a single click. It also supports Auto Lead-in Lines, Automatic Path Optimization, which significantly improves cutting efficiency.

Welding: Nitrogen or argon gas with purity above 99.99% is suitable for most metals. The required welding pressure ranges from 0.1–0.2 MPa, with a gas flow rate of 15–30 L/min (argon is required for welding titanium alloys).

Cutting: Compressed air, nitrogen/argon (purity >99.99%), or oxygen are commonly used as shielding gases.

- xTool air compressor and air dryer provide stable compressed air, enabling burr-free cuts at 0.6 MPa for 4mm stainless steel, 4mm aluminum, 3mm copper, 1mm carbon steel, and galvanized steel (1200W laser) when paired with xTool SaveGas™ Nozzle. This setup significantly reduces costs compared to gas cylinders.

- Nitrogen/argon (at 1.2 MPa) can achieve burr-free cuts for the same materials (1200W).

- Oxygen is primarily used for cutting carbon steel and galvanized steel above 1mm thick. With a dual-layer nozzle and focal extension tube at 0.06–0.07 MPa, it can cut up to 10mm carbon steel/galvanized steel (1200W).

Cleaning: Compressed air is sufficient, but nitrogen or argon is recommended for brighter, oxidation-free results.

The xTool MetalFab is capable of running continuously for 6-8 hours for standard cutting and welding tasks. For processing thicker carbon steel (>6mm), intermittent cooling breaks are required to prevent overheating.

The xTool MetalFab laser welder can operate with a voltage of 200-240V, running at full power with approximately 4200W. The maximum current is 21A. It is recommended that users connect it to an independent circuit rated at 220V-21A or higher.

For the US, we provide a NEMA6-50p or NEMA6-30p plug. For other regions, we provide power cables, and an electrician is required to install the appropriate circuit.

Laser Tube: Over 10,000 operating hours.

Cutting Head: Requires maintenance every 4 operating hours (regular cleaning is essential to maintain optimal performance).

Yes, we are building a global localized service network, with established local service teams in the U.S. and Europe. You can access:

- 24/7 online support (via email, live chat, or phone).

- 1-on-1 dedicated warranty assistance.

- Demo room reservations for in-person machine testing and material trials.

You can access the after-sales policy, shipping policy, warranty policy via the link.