Screen Printing: The Ultimate Guide

Almost a millennium ago, before the introduction of electricity and computers, when there was no formalized printer, people still had a manual process to print - screen printing. A process first used by the Chinese, back in the 10th century for printing design on fabric.

Over the centuries, it reached the rest of the world. The use case expanded from fabric; it was used on paper, wood, metal, and glass. Still, in the 21st century, it’s the most popular commercial method for printing designs on apparel.

This article explains the whole screen printing process, its applications, and modern adaptations with the introduction of new tools. In the end, we also compare it with other popular printing methods.

In This Article

- What Is Screen Printing?

- How Does Screen Printing Work?

- Pros of Screen Printing

- Pros of Screen Printing

- How xTool Screen Printer Reinvents Screen Printing?

- Applications of Screen Printing

- Screen Printing vs Other Printing Methods

- Screen Printing as a Business: How Good is It?

- FAQs of Screen Printing

- Conclusion

What Is Screen Printing?

Screen printing is a method of transferring an image onto a surface, typically fabric or paper, by pressing ink through a mesh screen. You place the screen on your material, spread ink over it, and then use a tool called a squeegee to push the ink through the screen and onto the surface. The areas of the screen that are blocked off don't let ink through, which creates your design.

Each color in the design requires a separate screen. This process lets you make vibrant, long-lasting prints, and it’s really popular for making things like T-shirts and posters.

How Does Screen Printing Work?

Screen printing is known to be a time-consuming process, which starts with stencil preparation, cleaning, drying and finally spreading ink through the screen.

Let’s explore the traditional screen printing process.

What Do You Need for Screen Printing?

To follow the traditional process, you will need these tools:

- Mesh Screen: Finely woven fabric (polyester or silk) stretched over a frame

- Emulsion: A light-sensitive coating applied to the mesh screen

- Scoop Coater: A special tool for applying emulsion onto the mesh screen

- Transparent Film: Used to print the design that will be transferred onto the screen

- Printer: Prints the design onto the transparent film

- Exposure Unit: Emits strong light to harden the emulsion on the screen

- Inks: Special screen printing inks, usually plastisols, for creating the design on the chosen surface

- Squeegee: Used to spread the ink through the screen onto the substrate

The Step-by-step Screen Printing Process

After you have got these tools, you can follow the procedure for screen printing:

Step 1: Take a mesh screen stretched tightly in a frame. This makes sure the screen smoothly absorbs and transfers the ink during printing.

Step 2: Coat the screen with a layer of photo-sensitive emulsion using a scoop coater. This layer should be fully opaque and even across the mesh, just like a plain canvas we use for drawing.

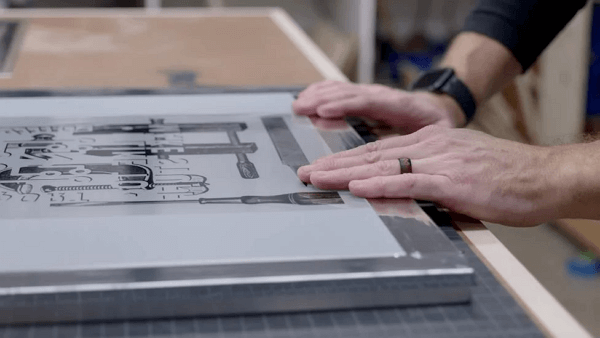

Source: ©ILiketoMakeStuff – YouTube

Step 3: Print the required design on a transparent film. Place it on top of the coated mesh and then fix it with transparent tape.

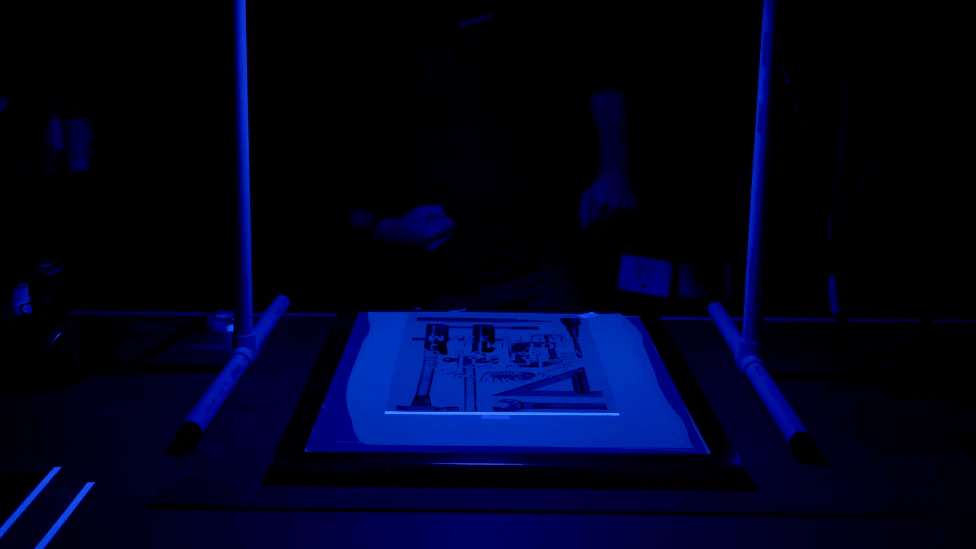

Step 4: Expose the mesh screen to a strong light source. The emulsion not covered by the design hardens due to the light while the rest of the emulsion is soft and can be removed.

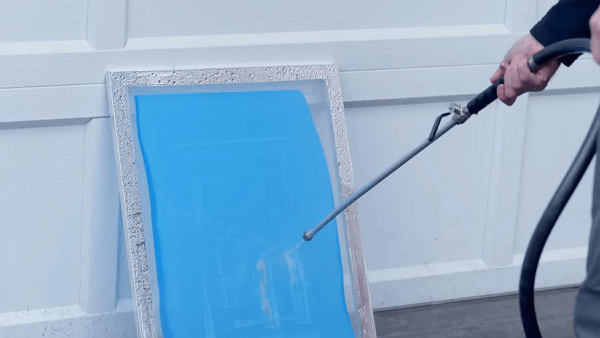

Step 5: Wash the screen with pressurized water. Wash and remove the sections not cured by light. This leaves you with a desired pattern.

Step 6: Let the screen dry. Use it when it doesn’t have any water droplets.

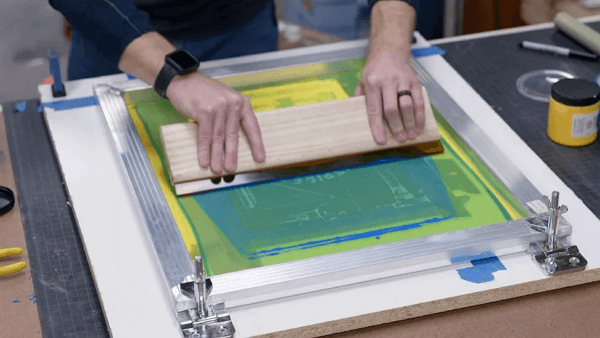

Step 7: For printing, place the mesh over the chosen printing surface. Pour screen printing ink on the mesh and spread it with a squeegee.

XTOOL SCREEN PRINTER

3-Step Easy Screen Printing

It utilizes laser to engrave the stencil on the screen, dramatically

improving the efficiency in screen printing.

Pros of Screen Printing

Despite being an ancient process, screen printing is still relevant and in fact a popular printing technique due to these advantages:

1. Durability with Plastisol Inks

Screen printing utilizes plastisol inks, which are known to last for years. These inks form a thick layer on top of the fabric. The screen printed designs last through numerous washes and extend use without fading or wearing out.

2. Vibrant Colors

Screen printing involves applying a thick viscous layer of ink, which is exceptionally bright and vivid. The designs are quite noticeable, even on darker materials.

3. Pantone Color Matching

Screen printing excels in color accuracy. You can easily form any color through Pantone matchmaking. It means the exact shades and tones of a design can be reproduced faithfully.

4. Versatility

This printing technique is suitable for a variety of materials, including textiles, wood, paper, glass, and metal. Such versatility is beneficial for diverse product applications across different industries.

5. Cost-Effectiveness for Bulk Orders

Although initial setup costs can be high in case you follow the traditional method, screen printing becomes more economical in larger volumes. Once you have made a stencil, it can used for replicating multiple designs. This makes the process ideal for bulk production.

6. Unique Textural Qualities with Special FX Inks

Screen printing allows the use of special effects inks, which are compatible only with this method. These inks create unique textures and effects (like metallic or glow-in-the-dark) that add a distinctive touch to the printed items, enhancing their appeal and value.

Cons of Screen Printing

If you opt for the traditional route, the process may be disadvantageous in terms of time, cost, space, and effort.

1. Time-consuming

Preparing a single silkscreen stencil through the regular way is a laborious and time-intensive job. From initial design setup to emulsion and drying, you end up spending days on one design.

XTOOL SCREEN PRINTER

3-Step Easy Screen Printing

It utilizes laser to engrave the stencil on the screen, dramatically

improving the efficiency in screen printing.

2. Expensive for Smaller Runs

Screen printing requires the same setup regardless of the print quantity. Even if you want to prepare a single-screen print, you still have to follow the long process, which isn’t cost-effective for single-run designs.

3. Setup Occupies Space

Traditional screen printing equipment – the screens, drying racks, and storage for inks and materials – is bulky and occupies much space. Add to that, the complementary processes, you’ll probably need an extra room just for screen printing.

How xTool Screen Printer Reinvents Screen Printing?

The traditional method is quite time-consuming and expensive, especially the stencil creation phase, which can easily take a couple of days. To make things easier, we have introduced a new method, xTool Screen Printer, to easily screen print at home. This method reduces the screen printing time to just a couple of hours.

Screen Printing: 3-Step xTool Method

Step 1: Insert the provided pre-coated screen in the xTool EasyStretch frame. Make use of its tensioning strips to fully stretch the screen. Ensure the screen is smooth with no folds.

Step 2: Place the setup (coated screen with frame) inside the laser engraver. You may use xTool S1 or other xTool laser machine. Load the stencil design in the laser software (xTool Creative Space). The engraver removes coated areas based on the design, forming the stencil on the screen.

Step 3: After engraving, remove the stencil and fix it in xTool Screen Printer. Make adjustments based on material height. Add ink to the screen and spread it evenly with a squeegee.

That’s all, your project is completed!

To follow this method, you’ll need a set of new equipment: a Laser engraver and xTool Screen Printer.

Laser Engraver

For design creation, you no longer need to separately print the design and then wait for hours for the design to settle in the exposure room. Just place the mesh screen frame inside a laser engraver, and engrave the design you want. It’s a job of minutes.

The laser machine is much more accurate compared with the traditional design method as it offers a motion accuracy of 0.01mm, preserving all minute details. The added benefit of getting a laser engraver: you can use it for a range of other tasks, besides screen engraving.

crafts made with xTool laser engravers

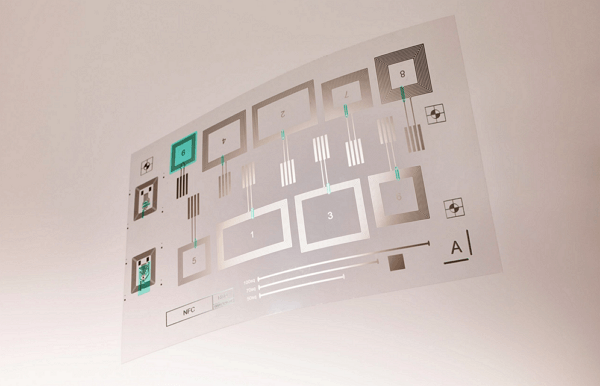

xTool Screen Printer

xTool Screen printer is offered as a complete package for screen printing. The kit has pre-coated screens, a frame, and a set of inks.

With pre-coated screens, you no longer need to prepare a stencil for screen printing. All you have to do is place that screen in our EasyStretch frame, which has 4 tensioning strips and 6 pull wrenches. Preparing the mesh screen just takes 30 seconds.

The screen printer is adaptable too. It has a quick-release clamp for easy removal and switching frames when doing multi-color printing. Plus, there are adjustments for height to fit in different size objects.

Applications of Screen Printing

It’s fair to say screen printing is a widely used commercial printing technique, with applications across a range of industries. Its most known applications are:

Textile Industry

Earlier back in the 10th century, the Chinese invented it for making designs on clothing items. Still, it is being known for that, particularly t shirt printing. Besides that, it’s used for making vibrant designs on bedsheets, caps, scarves, and all sorts of garments.

XTOOL SCREEN PRINTER

3-Step Easy Screen Printing

It utilizes laser to engrave the stencil on the screen, dramatically

improving the efficiency in screen printing.

Art Prints

Screen printing allows for making prints of art simple and more natural. You can apply it to any surface like paper, wood, or other favorite items.

Home Décor

You can personalize and create multiple home décor through screen printing. For example, you could make a DIY clock by screen printing the numbers and adding an emblem, or create a welcome sign for your home.

Promotional Items

It’s popular for making promotional items. You can use it for corporate marketing (promotional business cards, bags) and giveaways.

Product Labels and Packaging

Many product labels, stickers, and packaging materials are produced using screen printing, offering durability and high-quality finishes.

Signage and Posters

Road safety signs, banners, and retail displays, which require large, eye-catching graphics, are also made with made with screen printing.

Automotive Plates

In the automotive sector, the technique is used for producing vehicle graphics, decals, and registration plates.

Electronics

In the electronics industry, screen printing is used to create circuit boards, labels, and membrane switches. The keyboard keys are also labeled with this technique.

RELATED: unique screen printing ideas

Screen Printing vs Other Printing Methods

What’s the Difference between Screen Printing and Heat Transfer?

In heat transfer printing, a design is first cut onto vinyl or printed on heat transfer paper and then heat-pressed onto the fabric's surface, where it adheres as a separate layer. Whereas in screen printing, ink is directly applied to the material through a mesh screen stencil.

RELATED: Screen Printing vs Heat Transfer

What’s the Difference between Screen Printing and Digital Printing (DTF)?

In digital printing, ink is sprayed directly onto the material in the form of microdroplets. On the other hand, screen printing involves pressing ink through a prepared stencil onto the material. Digital printing usually uses water-based inks, while screen printing often uses discharge or plastisol inks.

RELATED: Screen Printing vs Digital Printing(DTF)

What’s the Difference between Screen Printing and Sublimation Printing?

Sublimation is printing design on a special transfer paper, and heat pressing to transfer the ink into the material. The heating turns the ink into a gas, which then bonds with the material. It works best on light-colored fabrics for making detailed designs.

In contrast, silk screen printing applies ink directly onto the material through a mesh screen. It’s suitable for vibrant, high-opacity designs on a variety of material.

Screen Printing as a Business: How Good is It?

According to Report Linker, the screen printing business is projected to grow, from a market size of $3.2 billion in 2022 to an impressive $11.2 billion by 2030. This growth trajectory suggests a thriving industry with expanding opportunities.

The diversity in industrial applications – from textiles to electronics and promotional items – means that the market is also broad and varied. Additionally, the rise in demand for personalized products provides a fertile ground for silk screen printing businesses.

For hobbyists or those looking to start a side venture, screen printing is a relatively low-investment business to enter, especially with compact and affordable screen printing machines like the xTool Screen Printer.

FAQs on Screen Printing

How Long Does Screen Printing Last?

Screen printing typically uses plastisol inks, known for their longevity. These prints can last for years. However, improper folding or bending may cause cracks over time.

Will Screen Printing Ink Wash out?

Screen prints with plastisol inks do not wash out. However, prints made with water-based inks may fade and wash out gradually.

Conclusion

Despite being a centuries-old process, screen printing still remains relevant. The reason: the quality, durability, and cost-effectiveness of the method compared to other methods. It was known to be a tedious process, but no longer. With xTool’s 3-Step screen printing method, it’s now a job of hours. Want to test that? Get your xTool screen Printer now!