Over the last couple of years, more and more people have opted to work from home and have obtained the “side hustle” mentality. For many of those people, that involves using their artistic abilities to make products that others want to buy utilizing hobby machines such as 3D printers or laser cutters. We call these people “Makers”.

In this article we’ll discuss the differences between 3D printers vs. laser cutters, especially as it relates to

In This Article

- Some Historical Contest about 3D Printing and Laser Cutting

- 3D Printing vs. Laser Cutting: Definition Comparison

- Laser Cutters vs. 3D Printers: Which Should I Choose?

- Conclusion

Some Historical Contest about 3D Printing and Laser Cutting

The internet is full of promises and advertisements for just such “side hustle” makers. These days there is a machine for everything.

Twenty years ago, if you wanted to be a maker, the technology was either limited to movement along 2 axis, right and left, and backwards and forwards such as in an inkjet printer.

Someone slapped a blade on a 2 axis printer and Vinyl cutters were born.

3 axis support for 3D printers and laser cutters existed but it was way too expensive for the home user. And it was usually pretty large in size.

Somewhere along the line in around the early 2010’s, DIY enthusiasts began figuring out how to add 3rd axis support INEXPENSIVELY and homemade 3D printers and laser cutters began to appear on the landscape.

3D Printing vs. Laser Cutting: Definition Comparison

You might be wondering which technology is better for your side hustle: 3D printing or laser cutting. Both of these technologies can help you turn your creative skills and ideas into reality, but they also have different features and limitations that you need to consider.

The main difference between 3D printing and laser cutting is the way they create objects. 3D printing is an additive process, which means it builds objects layer by layer from a material, usually plastic or metal. Laser cutting is a subtractive process, which means it cuts out shapes from a flat sheet of material, usually wood or acrylic. 3D printers can create complex and intricate shapes that are difficult or impossible to cut with a laser cutter, while laser cutters can create precise and smooth edges and also do engraving and etching. Depending on the type of product you want to make and sell, you might prefer one technology over the other.

What Is a Laser Cutter?

A laser cutter uses a laser beam to cut all types of designs and patterns into a material. Depending on the laser (ususally diode, CO2 or fiber lasers) and the material, the laser might vaporize, melt or burn the material in order to create the design.

If you’ve been wondering what a laser cutter is and why you’d use one, the simple answer is that it’s a great non-touch way to create highly intricate designs with precision.

Laser cutters are most often used on glass, wood, gemstone, paper, leather, plastic and metal. This amazing technology is credited to Kumar Patel, who created the first CO2 laser in 1963.

Despite being called a cutter, modern laser cutters are used to engrave, cut and mark materials.

Depending on what you want to do, you can choose between three different main types, including:

Diode laser cutters– These use diodes as the laser source, and they are best for beginners as they're usually cheaper.

CO2 or gas laser cutters– These are powered by CO2 and other gases, such as helium and nitrogen. They work well for multiple types of materials, especially non-metals.

Fiber laser cutters– These use fiberglass and are often referred to as solid-state lasers. They work well for metals.

What are the pros and cons of laser cutting compared to 3D printing?

Compared to 3D printing, one of the advantages of laser cutting is that it can cut objects with high precision and smooth edges, which are also ideal for engraving and etching.

Laser cutting can also work faster than 3D printing, as it only needs to cut the outline of the object.

Moreover, a laser cutter can be cheaper to buy, as it works faster and only requires a flat sheet of material that are cheaper to produce than it is to produce powder or resin for 3D printing.

However, laser cutting can only cut flat or thin objects, which means that multiple laser-cut pieces must be assembled together if three-dimensional shapes are to be created. There’s also a risk of toxic emissions, depending on the material. Thicker materials are a bit harder to deal with and you may have some occasional burnt edges.

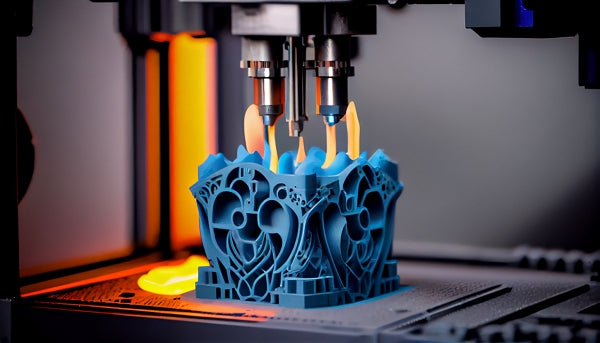

What Is a 3D Printer

What is a 3D printer, how does a laser come into play and can 3D printers laser cut? These are reasonable questions.

First, let’s talk about how 3D printing actually works. A 3D printer takes a CAD file or a 3D scan and uses it to form an item by adding thin layers of sintering powder or resin until the item is fully formed.

A laser 3D printer cures the resin into the hardened plastic you’re used to seeing on 3D printed objects.

Thanks to its quick-printing abilities, you can print any custom component in just hours versus waiting weeks or months for a company to manufacture it using traditional methods.

As long as you can design it, a laser 3D printer can probably create it, even if it’s nearly impossible to make using standard molds.

Stereolithography 3D printers use lasers to cure resin, while Selective Laser Sintering 3D printers work with polymer powder to print objects particle by particle.

The best part is that 3D printers are becoming more affordable, and you can make money with 3D printing.

Some 3D printers can be converted into laser cutters or engravers by replacing the extruder with a laser module. This allows you to use the same machine for both 3D printing and laser cutting, depending on your project needs.

However, not all 3D printers are compatible with laser modules, and some may require additional modifications or accessories to work properly. Moreover, the quality and performance of 3D printer laser cutters may not be as good as dedicated laser cutters, as they have different design features and specifications.

What are the pros and cons of laser cutting compared to 3D printing?

3D printing can create complex and detailed shapes that are hard to achieve with laser cutting. 3D printing can also use materials that are not suited for laser cutting, such as ABS.

However, a 3D printer can be expensive to buy and maintain, as well as the materials needed for it. Furthermore, 3D printing can have lower accuracy and quality than laser cutting, depending on the printer and the settings used.

Laser Cutters vs. 3D Printers: Which Should I Choose?

So, you have decided to get yourself a side hustle to generate some extra income. There are several types of hobby machines and you have narrowed it down to either a 3D printer or a laser cutter/engraver.

In this section we’ll discuss which one could do the best for you in regards to earning some extra money.

3D printing vs laser cutting: Initial Investment and Start up Costs

Obviously the most important question anyone will ask is, “How much is this going to cost me?”. It is of course a great question and one with a lot of different answers.

Each technology has a couple of different entry cost points. But it should be noted that a lower buy-in cost may come with some surprises.

Machine cost

The 3D printer community has no shortage of suppliers, and no shortage of price entry points. After doing research you may find some machines that are darlings of the DIY community offered for very reasonable and tempting low costs.

The catch, however, is that the stock kits, while adequate, only become great platforms after applying the DIY community enhancements.

You might see articles or videos online telling you the modifications that you need to do to transform your printer into a powerhouse machine.

In other words you need to spend some serious time with the machine to upgrade it prior to it making you any money. Also, you should consider the implications to the manufacturer warranty once you have rebuilt the machine.

3D printers with a solid reputation right out of the box are available at much higher costs but the lead times are considerable. Order one today and it might come to you in 2 to 3 months.

The entry point for a decent 3D printer is probably around $600 to $700 but higher quality tiers are available.

Conversely the buy-in point for a laser cutter such as the xTool D1 Pro is also just over $600.

The xTool D1 Pro is currently “state of the art” for desktop lasers. A user, at a minimum will probably want an Air Assist kit which is important for creating clean engravings and even more important for cutting operations.

All things considered, the buy-in costs similar until you get to consumables. In order to use a laser engraver all you need is something to engrave on.

Material cost

To use a 3D printer you must purchase filament which is about $25 to $30 a spool. There are different kinds of plastics such as PLA, PETG, ABS, and FLEX which are common materials.

Each one of those types of plastics come in different colors. Unless you are printing one item in one color you’ll probably want a variety of colors for your customers.

3D printer filaments are hygroscopic which means they will absorb water and should be stored in low humidity conditions. Most serious 3D printing operations have special storage containers built that use desiccant materials to maintain low humidity.

In regards to laser consumables it depends on what you intend to laser engrave on.

Some popular items are tumblers, mugs, cups, leather patches, glass engraving, making jewelry or making signage. Consumable purchase costs can vary greatly depending on which direction you go with your business.

For example someone making earrings from

Finding Your Niche

This is the hard part. Finding something that customers want to buy and then finding a place to sell it in.

For me it was making sushi boards. I live near a large military community that has frequent post assignments in Japan. So consequently there are a large number of people in my area who have lived in Japan and for some reason they seem to want their very own sushi board. You just never know what that niche can be.

I have also found that real estate companies provide

Kids sports teams also have ceremonies at the end of the season and everyone gets a plaque or a tumbler with their name and number engraved on it.

Engraved pens and pencils are popular for giveaway items for small businesses.

The possibilities for finding your niche are almost endless but you have to find it, and then you have to exploit it. One good solid customer can really make your side hustle explode.

Study your local area and don’t just make the things that other makers are producing. Be unique, do your research, and you will surely find that item that people want.

Realistically, I think making and selling laser engraved or laser cut parts are more likely to turn you a profit than 3D printing parts.

I think it may be harder to find a 3D printed widget that will sell reliably. You are probably more likely to find customers for 3D printed parts just by advertising that you provide 3D printer services and will print requested items for a price.

The Learning Curve

Oh, the dreaded learning curve. You’ve never done anything like this before and you probably know that you aren’t going to buy a 3D printer or a laser cutter and just plug it in and start making money.

You are going to make mistakes, and you are going to waste material, and you are going to make a costly mistake or two. Or three.

With a 3D printer the only way to practice is to consume expensive filament materials.

With a laser you can practice on scrap wood or cardboard. You can also engrave on wood at extremely low power and then sand off the engraving with an electric sander and start over. You can wrap tape, or thick paper, or cardboard around an expensive Yeti and do a test burn before you do the final burn.

All I can say is that if you ruin a project, keep that material and use it for a test piece. That way it isn’t a total loss.

Anyone can learn to 3D print or laser engrave but the key to becoming a Maker and maximizing your profits is to learn how to cut material costs and to reduce waste. Maybe if you are cutting out keychains you might find a way to make 10 fits on your material instead of 8.

That is a layout feature usually referred to as “Nesting”. Maybe you can make a template to engrave 10 pencils or pens at one time perfectly instead of doing just one a time and every one being a little different.

Key elements like this can make your work stand out from your competitors and make you the sought-after artisan.

Payback Period: How Long Before You Make A Profit

You aren’t really making a profit until your initial investment in the machine and consumables are paid for. And you also have to factor in your training time and the materials you used to learn your craft.

Not long ago I saw a story where a guy bought a laser, spent a few days figuring out the rotary operations and then got an order for 300 tumblers to be processed. He literally paid for his initial investment with that first job, and then some.

While that is entirely possible, it is more likely you will need some time to find your niche product and build up your business via word of mouth. Like any worthwhile endeavor it can come down to what you put into it and your level of commitment.

It might be of some benefit to price items lower in the beginning to achieve a customer base. Word of mouth is powerful and even providing free items to influential people or businesses can pay huge dividends moving forward.

Conclusion

While both the technology and innovation of both the 3D Printer and Laser Cutter are remarkable, one device clearly stands out as the leader in regards to generating income and profit in your new home business.

Due to its portability, low power requirements, and ability to engrave or cut a variety of materials the laser engraver should be your one and only choice for making the most of creating personal wealth in your work from home business endeavor.

On their small business page, xTool provides advice and even offers home business kits for purchase to help you get your start.

Monthly payments with Affirm are also offered.

With the advent of reliable, powerful, and fast laser engravers there has never been a better time to begin to earn some wealth for yourself and your family.