xTool vs Glowforge: A Comprehensive Guide

Laser cutting isn’t just for industrial applications anymore. Thanks to compact desktop lasers, heavy-duty machines are now within reach of DIY enthusiasts and home crafters.

For years, Glowforge has been a leading name in the desktop laser market. However, the landscape is changing. The market now has several Glowforge alternatives. One notable competitor is xTool.

This article provides a detailed comparison between the flagship CO2 laser cutting and engraving machines offered by two leading brands: xTool and Glowforge.

In This Article

- xTool P2 vs Glowforge: A Quick Comparison

- xTool P2 vs Glowforge: Laser Type & Power

- xTool P2 vs Glowforge: Working Area

- xTool P2 vs Glowforge: Positioning Precision & Autofocus

- xTool P2 vs Glowforge: Compatible Materials

- xTool P2 vs Glowforge: Uneven Surface Engraving

- xTool P2 vs Glowforge: Software

- xTool P2 vs Glowforge: Safety Features

- xTool P2 vs Glowforge: Add-Ons

- Conclusion: Which One to Choose?

xTool P2 vs Glowforge: A Quick Comparison

The journey of Glowforge began nearly a decade ago with the launch of its CO2 laser machine, now known as the Glowforge Pro. Glowforge calls the product a 3D laser printer, but technically it’s a laser cutting and engraving machine. Besides CO2 laser models (Glowforge Pro and Glowforge Plus), the company has recently expanded its lineup to include two diode laser machines: the Glowforge Spark and Glowforge Aura.

xTool is a successor of a STEAM startup, Makeblock. The startup was founded in 2012 and made robotic modules and coding software for educational purposes. In 2021, they stepped into desktop laser cutters with the brand name xTool.

xTool is recognized for producing some of the most powerful diode and CO2 laser machines in the world. Their CO2 laser machine, the xTool P2, is particularly noted for being a close competitor to the Glowforge Pro. This article primarily focuses on the comparison of these two machines.

Here’s a quick comparison of xTool P2 and Glowforge:

| Specification | xTool P2 | Glowforge |

|---|---|---|

| Price | View | $4,995 (Pro)

$3,995 (Plus) |

| Laser System | CO2 laser | CO2 laser |

| Optical Power | 55W | 40W (Plus)

45W (Pro) |

| Engraving/cutting Area | 23.6” x 12.1”

(600×305mm) | 19.5” x 11” (495×279mm) |

| Engraving Speed | 600mm/s | ~141mm/s |

| Smart Camera (auto focus& workspace preview) | Twin 16MP | Twin Camera Setup |

| Auto Focus Precision | 0.001” | 0.004” |

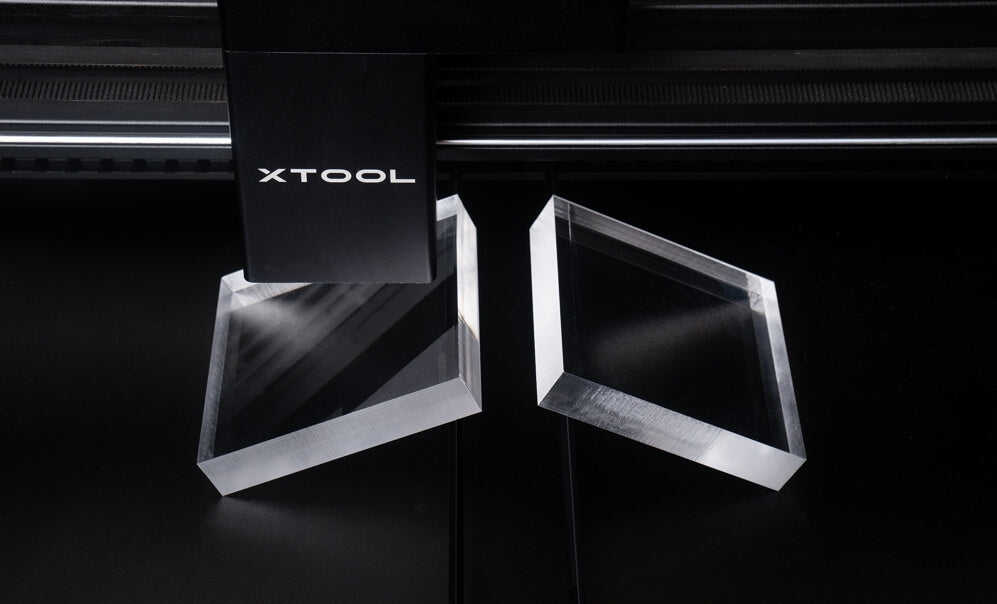

| Max. Material Cutting Capacity | Up to 20mm (acrylic) | ~12.7mm |

| Passthrough Slot | ✔️ | Pro ✔️ |

| Rotary Engraving | ✔️ | ❎ |

| Curved Engraving | ✔️ | ❎ |

| Software | XCS, Lightburn | Glowforge Print |

| Warranty | 12 month | 12 month |

xTool P2 vs Glowforge: Laser Type & Power

Both the xTool P2 and Glowforge models are equipped with CO2 laser modules, but their optical power varies. The Glowforge Pro model features a 45W CO2 laser, whereas the Glowforge Plus operates with a 40W laser. This allows the machines to cut through materials up to ½ inch thick (12.7mm) in a single pass. The exact top engraving speed of the Glowforge isn’t officially stated, but discussions from their community forums suggest it is around 141mm/s.

In comparison, the xTool P2 features a more powerful 55W CO2 laser module. This increased power enables the P2 to cut up to 20mm thick materials in one pass and achieve a top engraving speed of 600mm/s. As per laboratory tests, the P2 is up to 500% faster at cutting materials than other 40W diode lasers.

xTool P2 vs Glowforge: Working Area

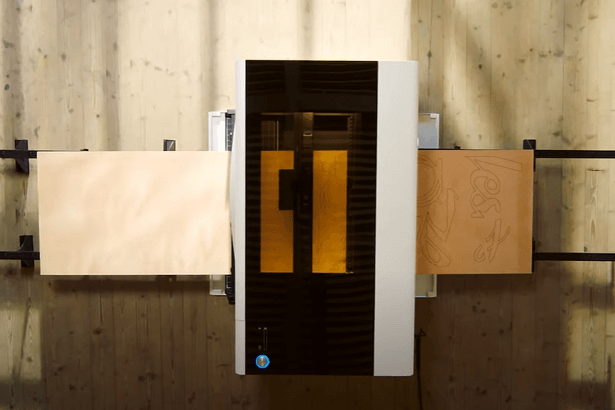

At first glance, the xTool P2 and Glowforge might appear similarly sized, but there are notable differences. The P2 offers a slightly larger working area of 600×305mm compared to Glowforge's 495×279mm.

Furthermore, the P2’s workspace is expandable, both in terms of length and height. Thanks to its automated passthrough slot and conveyor feeder, it can process sheets up to 118 inches long. An additional riser base elevates the machine to accommodate materials up to 8.5 inches tall.

The Glowforge Pro also includes a passthrough slot, which enables it to handle long sheets. However, it can only accommodate materials up to 2 inches high, and that's after removing the internal tray.

xTool P2 vs Glowforge: Positioning Precision & Autofocus

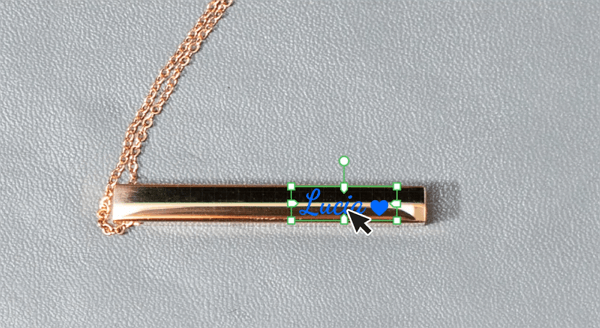

This is one of the areas where P2 is far ahead of Glowforge in terms of tech. We see that most desktop laser machines have a dual camera: one panoramic camera for overall workspace preview. And another close-range camera on the laser head for the auto-focusing. The two-camera setup is necessary as most panoramic cameras have blind spots due to their positioning.

Glowforge incorporates a wide-angle camera atop the machine which provides a complete preview of the printing area with an accuracy of 0.25”. Additionally, a macro camera mounted on the laser head provides detailed precision with an accuracy of 0.004”. Glowforge doesn’t mention the specific resolutions of these cameras.

Conversely, the xTool P2 enhances this concept with its dual 16MP camera setup, comprising a 180-degree panoramic camera and a close-range camera. This 16MP resolution is unparalleled in the smart cutting machine market, significantly outshining competitors like OMTech Polar, which typically feature only 5MP cameras. To put it into perspective, a 16MP camera provides 16 million pixels, dwarfing the 5 million pixels of a 5MP camera and even surpassing the roughly 8 million pixels of 4K resolution.

Besides the camera, xTool’s autofocus technology leverages LIDAR and dGPU for impeccably precise measurements, with an accuracy of 0.001” – it’s 4 times more than Glowforge.

xTool P2 vs Glowforge: Compatible Materials

Both the xTool P2 and Glowforge, being CO2 laser machines, share the capability to cut and engrave a wide array of materials. However, the difference in their power outputs may influence the thickness they can handle in a single pass.

These laser cutters can process materials such as wood, paper, fabric, leather, rubber, acrylic, and cardboard. They also support engraving on stone, glass, and coated metals. However, it’s important to note that neither machine can engrave bare metals.

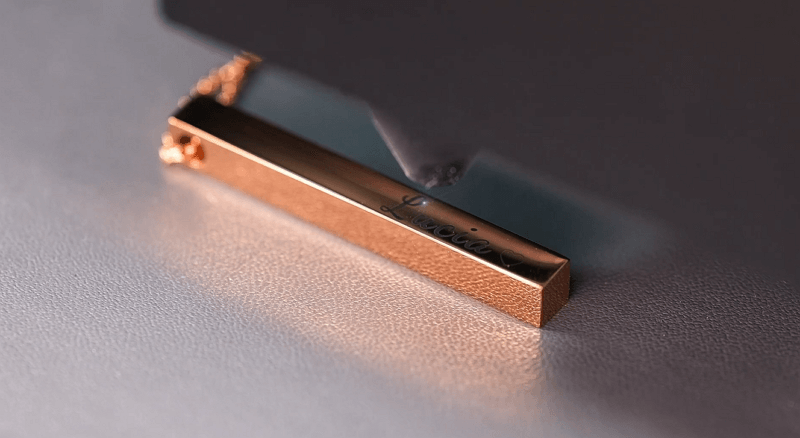

xTool P2 vs Glowforge: Uneven Surface Engraving

Engraving on flat surfaces is standard across desktop laser engravers. Glowforge does support that but xTool P2 is one of the rare machines to support uneven/curved surface engraving. This capability is attributed to its CurveAce™ Technology, which creates a 3D model of the surface. The machine's z-axis laser head then automatically adjusts its focus to accurately engrave over the contours.

Furthermore, P2 also supports rotary engraving on cylindrical objects like tumblers, spherical balls, and rings. This functionality requires the use of a separate attachment, the RA2 Pro.

xTool P2 vs Glowforge: Software

The software component is crucial as it helps in transferring designs to the laser machine and managing its operations. Glowforge operates exclusively through its proprietary software, Glowforge Print. This web application is compatible with various operating systems, including Windows, Mac, Linux, and Android. It allows users to scan drawings and place them onto materials. Additionally, Glowforge offers an online catalog of ready-made designs and templates.

In contrast, the xTool P2 is compatible with the popular laser control software LightBurn, in addition to its own custom software, xTool Creative Space (XCS). XCS is versatile software that is capable of functioning on most operating systems (Windows, MacOS, iPadOS, IOS, Android) both online and offline. It enables users to drag and drop designs onto materials, perform batch engraving on multiple objects, and create new design ideas with xTool generative art, known as AImake. XCS also provides access to thousands of pre-made design templates for users.

xTool P2 vs Glowforge: Safety Features

Given the powerful lasers both the xTool P2 and Glowforge utilize, safety is a significant consideration. Glowforge incorporates basic safety sensors to warn users of unexpected movements or temperature increases.

However, the xTool P2 adopts a more comprehensive approach to safety. It is fully enclosed, featuring a laser light filtering lid, an emergency stop button, an automatic lock to secure the machine during operations, and a multi-warning system to monitor the safety of interior components. Notably, the P2 includes the world’s first fire safety kit for laser cutters, which is capable of detecting and extinguishing flames within seconds.

xTool P2 vs Glowforge: Add-Ons

Add-ons are additional attachments introduced to enhance the working capabilities of a machine. In this aspect, the xTool P2 surpasses Glowforge due to a broader range of available attachments.

xTool provides several useful add-ons, including a riser base to accommodate taller objects, a smoke purifier for indoor work environments, a rotary attachment for cylindrical objects, a conveyor feed for processing long sheets, and a fire safety kit to extinguish fires.

Conclusion: Which One to Choose?

Glowforge has established itself as a top contender in the laser cutter market. Yet, when we compare it to the xTool P2, the latter stands out in terms of performance.

The P2 offers greater work area, faster speed, higher precision, and a wider array of attachments, enhancing the scope of projects one can undertake. Therefore, for those entering the crafting business or looking to expand their creative capabilities, the xTool P2 is a highly recommended option.