How Much Does A Laser Cutting Machine Cost?

Buying a laser cutter is not an act of impulse, like buying a candy bar in the grocery checkout line. Instead, it’s like investing in a new car or even a house - substantial, impactful, and sometimes, a bit nerve-racking. This significant investment can be pretty overwhelming, especially when you dive into the technicalities and the price tag.

However, knowing what you’re paying for is vital. It gives you the power to make well-informed decisions and ensures you are investing in a machine that offers real value for your money.

This article is here to shed some light on the mysteries of laser cutter pricing and discuss factors that influence the cost of laser cutting machines.

In This Article

- Factors Influencing the Cost of Laser Cutting Machines

- How Much Will a Laser Cutting Machine Cost You?

- Related Questions

Factors Influencing the Cost of Laser Cutting Machines

Understanding the cost of laser cutting machines is like making a puzzle. Several pieces fit together to create the total price. These pieces, or factors, can cause the cost to go up or down, depending on what you need from your machine.

Here’s a list of key factors that influence the price of laser cutting machines:

1. Type of Laser

The type of laser used in the machine plays a big role in the price. For example, CO2 lasers are generally cheaper because their parts are easy to sort and used in multiple other devices. On the other hand, fiber lasers are more expensive due to their complex working mechanism which requires high-end parts. While there’s another type that is much cheaper than these two, the Diode laser; it has a small size and fewer parts. Hence, the least cost.

2. Power of Laser

Laser Power is another significant factor that raises the price. More powerful lasers can cut through thicker materials faster, but they do cost more. The reason is straightforward, a machine needs more advanced parts to handle more intense laser beams. So, it’s a kind of direct relation-the more power you need, the more cost you’ll have to pay.

3. Material Compatibility

Some lasers are like jacks-of-all-trades. They can work with many different materials. Other lasers specialize in certain types of materials. Machines that can handle a wide range of materials might cost more. They need heavy-duty parts to handle more power and thickness. This again adds up cost.

4. Cutting Ability

Laser cutters can do two main things: cut and engrave. Some machines excel at one or the other. If you need a hybrid machine that’s really good at both, it’s obvious that you would have to pay a bit more.

5. Working Size

The dimensions of the working area, often referred to as the bed, do influence the cost of the machine. Larger beds offer the convenience of handling bigger projects. But remember, the production of these larger machines demands more raw materials, which consequently raises their price. So, as the bed size increases, you can expect the machine's price to follow suit.

6. Cutting Speed

Just as a fast car tends to cost more than a slower one, a fast laser cutter is usually pricier than a slower machine. Since the cutting process is controlled through motors, for higher speeds you will need to add a more powerful motor, which makes it pricier.

7. Add-On Features

The more add-on features you add, the pricier the machine gets. Features like an integrated camera, a cooling system, or an auto fire-extinguishing system can push up the price of the machine. Although these features add convenience, efficiency, and accuracy, they come at an additional price.

XTOOL S1

Best Laser Cutter for Beginners

Verified as a class 1 safe laser cutter and equipped with easy-to-operate features, S1 is a perfect option for beginners.

Learn MoreHow Much Will a Laser Cutting Machine Cost You?

Laser cutting machines typically range in cost from $500 to over $ 600,000. That’s a wide span, right? It is like saying a car can cost anywhere from the price of a second-hand scooter to a brand-new sports car.

Now, to make this wide range a bit more digestible, we can break it down into more manageable chunks. One effective way is to segment these machines based on their working principles.

Another method is to categorize them based on their power and the type of materials they can handle. These machines range from light-duty machines perfect for thin plastic and wood to heavy-duty giants that can slice through thick metal.

Laser Cutter Costs Based on Working Principles

Before revealing the costs, you need to know the three common types of laser machines available in the market, CO2 laser, Fiber Laser, and Diode Laser.

Each one operates on a unique principle and is suited for specific applications. Therefore, the price also varies among these types. Let’s take a closer look at each of these:

1. CO2 Laser Cutters

CO2 lasers have been around for a while, but they are still widely used due to their versatility. They generate a laser by electrifying a gas mixture, typically carbon dioxide.

CO2 lasers are the go-to machines for cutting, engraving, and marking non-metal materials such as wood, acrylic, and glass, but they can handle plated and painted metals too.

Given their versatility and wide range of applications, these machines fall into a moderate price category. The price of these machines is largely dependent on the power and material they can cut. The smaller versions can start as low as $1,000 while big industrial systems go beyond $100,000.

2. Fiber Laser Cutters

Fiber lasers are the latest development in laser cutting technology, and they are becoming increasingly popular for good reasons. They use a seed laser that's amplified within a glass fiber. This process allows for extremely precise cuts, especially in metals like steel and aluminum.

Fiber laser machines are primarily used in the industrial sector for applications requiring high precision and speed. So, the costs of these machines, due to their advanced technology, power, and size, are much higher than CO2 lasers.

You might be looking at a price tag ranging from $3,500 to over $600,000, depending on the power output and added features.

3. Diode Laser Cutters

The workhorse of the bunch, diode laser machines are straightforward and compact. They generate lasers from diodes, small semiconductor devices that emit light when current is applied.

These machines are ideal for engraving and cutting thin materials, making them perfect for hobbyists and small businesses.

The best part is they are the most affordable of the three. Diode laser machines typically range in cost from $500 to $2500, making them an excellent entry point into the world of laser cutting.

Rough Price Estimates:

Here’s a rough cost estimate of all three types of laser cutting machines.

| Type of Laser Machine | Price Range |

|---|---|

| Fiber Laser | $3,500 – $600,000 |

| CO2 Laser | $1000 – $100,000 |

| Diode Laser | $500 – $2500 |

Laser Cutter Costs Based on the Handling Materials

While understanding the types of laser cutting machines gives us a preliminary pricing idea, a deeper understanding comes when we consider the materials these machines handle.

Different materials have varying levels of hardness and thickness, requiring different power levels and types of machines. So, let’s delve into the cost dynamics based on different materials:

1. Metal Laser Cutting Machine

Primarily, these are the domain of fiber lasers due to their efficiency with reflective metals. Metals are tough and require high power (0.5 to 12 kW) for cutting, hence machines cutting metals are typically high-powered beasts.

Moreover, the wavelength of fiber laser is in the range of 780 pm to 2200 pm, which is typically absorbed by metals. Some metals reflect CO2 laser; so mostly you’ll find fiber lasers for them.

The price of fiber laser machines for cutting metals starts at around $3,500 and goes upward to $600,000.

2. Acrylic Laser Cutting Machine

Acrylic cutting is typically handled by CO2 lasers. They offer a smooth finish and can efficiently cut and engrave this material.

Acrylic isn't as hard as metal, so these machines don't need as much power. Secondly, CO2 lasers emit infrared wavelengths, which are readily absorbed by acrylics. Speaking of prices, these machines usually fall in the moderate range, from $1,000 to 5,000.

A diode laser may also be used. However, diode lasers can only handle opaque acrylic. Diode lasers for acrylics are available for under $2000.

3. Wood Laser Cutting Machine

Wood can be processed effectively by both CO2 and diode lasers. They’re well-suited to handle the burning process involved in wood cutting and engraving.

The cost again is moderate. If you buy CO2 machines, you can expect to pay something between $1000 to $4000. While for diode laser the pricing will be likely between $1000 to $2000.

4. Plastic Laser Cutting Machine

Plastic, especially thin sheets, can be easily handled by diode lasers or lower-power CO2 lasers. They don’t require much power; hence the cost is considerably lower. Prices usually start from $500 and can go up to $5,000. For industrial plastic-cutting CO2 machines, the price goes beyond 100,000.

5. Paper Laser Cutting Machine

Paper cutting requires precision more than power, making diode lasers an excellent fit for this task. Given their lower power requirement and smaller size, these machines are also the most budget-friendly, with costs ranging from $500 to $2500.

6. Leather Laser Cutting Machine

Leather is another material that laser machines can handle adeptly. For leather cutting and engraving, CO2 lasers (40-50W) are typically the preferred choice. They can cleanly cut and engrave intricate designs on leather, making them ideal for industries like fashion, upholstery, and automotive.

The power required to cut through leather is not as high as metal but higher than materials like paper, so these machines often fall in the middle to high price range.

Depending on the machine's power and additional features, you can expect to pay anywhere between $2,000 to $6,000 for a leather laser cutter.

Rough Price Estimates:

The table illustrates the cost of different laser cutting machines based on material compatibility.

| Material | Type of Laser Machine | Price Range |

|---|---|---|

| Metal | Fiber | $3,500 – 600,0000 |

| Acrylic | CO2/ Diode Laser | $1000 – 5000 / $500 – 2000 |

| Wood | CO2 / Diode Laser | $1000 – 5000 / $500 – 2000 |

| Plastic | CO2 / Diode Laser | $500 – 5000 |

| Paper | Diode Laser | $500 – 2500 |

| Leather | CO2 Laser | $2000 – 6000 |

Related Questions

1. What factors influence the cost of a laser cutting machine?

The cost of a laser cutting machine is a function of multiple factors. These include the type of laser used (fiber, CO2, or diode), the machine’s power output, materials compatibility, working area size, speed, and added safety features.

2. What is the cheapest laser cutting machine?

In terms of price, compact diode laser cutting machines are typically the most affordable. However, they’re suitable for cutting thin materials like paper and thin wood. They are ideal for hobbyists and small businesses. Prices for these machines start from around $500 and can go up to $2500.

3. Is laser cutting expensive?

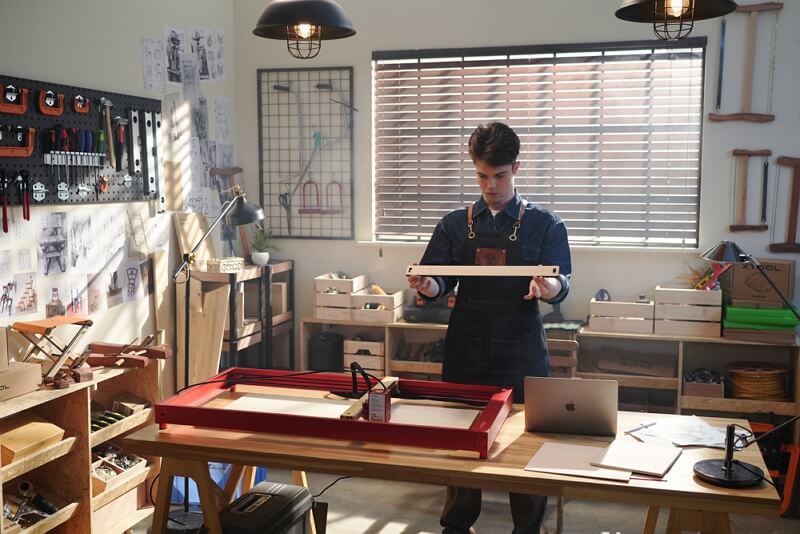

Yes, on an industrial scale, the investment may be high. But in the longer run, it reduces production costs due to its efficiency and precision. If you’re a hobbyist buying a compact desktop laser-like xTool S1 isn’t a huge investment.

4. Is laser cutting profitable?

Laser cutting can be a profitable business, depending on various factors such as the type of services offered, the materials being cut, and the market demand. For instance, a low-cost woodworking business, initiated with a desktop laser-cutting machine is profitable.

Conclusion

Venturing into the world of laser cutting machines can feel like a daunting journey, with many variables to consider. It’s not about choosing the most powerful machine or finding the one with the lowest price tag. It is always about understanding the dynamics of different machines and their compatibility with your specific needs and budget.

The type of laser, the materials it can handle, the machine's power output, and the additional features all contribute to the cost and functionality of a laser cutting machine. Whether you're a hobbyist looking for a cost-effective entry-level machine or a business seeking a high-powered cutting beast, there’s a machine out there for you.